RFID Tags

RFID tagging is done to track and monitor movement of assets within a building or movement from one location to another, such as manufacturing facilities to warehouses, yards, and distribution centers. RFID tagging also helps to manage inventory of assets, tools and raw material. RFID tags are used to track critical assets in industries such as IT, manufacturing, laboratory, oil and gas, and construction to locate the assets instantly, perform inventory audits easily and effortlessly, maintain compliance regulations and manage assets efficiently.

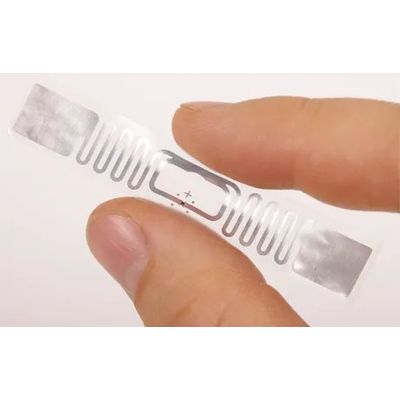

The RFID Tag has three components:

Antenna - The antenna is unique for each type of tag. Its primary function is to receive and transmit RF signals. For active RFID tag, it transmits the signals and for passive and semi-passive RFID tag, it reflects the signals. For passive RFID tag, the antenna powers the IC by collecting power from the radio waves. Antennas are generally designed and made by tag manufacturers.

Integrated Circuit (IC) / Chip - The IC, also called as electronic circuit or microchip or chip, has a logic unit that handles memory allocation to store data and make decisions. The memory is divided into different blocks called banks that process information, send and receive information, and has anti-collision protocols. Every IC type is unique and there are very few semiconductor manufacturers who make ICs. The only difference between various types of ICs is the number of bits in the respective memory banks.

Substrate - This layer holds all the other components of the RFID tag. It is made up of thin flexible plastic or rigid material. It depends on the type of tag and the environmental conditions that tag is subjected to. Some of the materials that are used to make substrate are polymers, polyvinyl chloride, styrene, polyesters and paper.

AssetPulse offers different types of RFID tags that are being used in a wide range of use cases in various industries. RFID tags differ based on the size, form factor, read range, ruggedness, tolerance to certain environmental conditions, and aesthetics. Therefore, it is essential to choose the right type of RFID tag that meets the requirement and yields the best results.

AssetPulse offers a wide range of RFID tags including Active and Passive RFID tags.

Label and Inlay RFID tags are thin, flexible, weigh less than a gram, vary from less than an inch to several inches and are cost-effective. The difference between these two types of tags is inlay tags are clear and they are manufactured with or without adhesive whereas label tags have a paper or polyplastic face on which graphics or text can be printed to read clearly.

Hard RFID tags are rigid and thick, and are more expensive than label and inlay RFID tags. They are made up of ceramic, ABS, steel, polycarbonate, polypropylene and polystyrene. These tags vary in weight ranging from 0.2 grams to over 250 grams. The size varies ranging from the size of a pencil eraser to a license plate.