- Home

- Companies

- Henry Simon

- Products

- Henry Simon - Model HSRM - Roller Mill ...

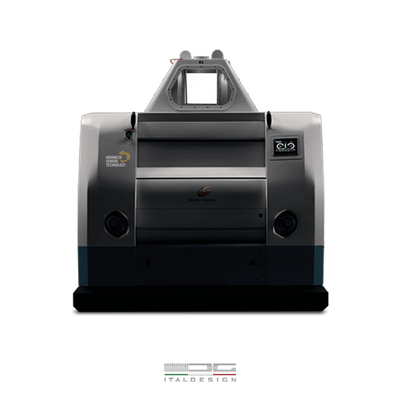

Henry Simon - Model HSRM -Roller Mill for Grains and Cereals

The HSRM Roller Mill is intelligently designed with the state-of-the-art control systems for precise and effective grinding operation for the wheat, maize (corn) and various grains. This is a new generation roller mill equipped with Advanced Sensor Technology, which enables to track the machine status in real time, moreover records data for optimum machine operating conditions.

Having the same spirit for innovation since 1878…

The new HSRM Roller Mill combines the best of Henry Simon experience in grain milling technology for over 140 years.

The roller mill is used in the grinding process of grains and cereals such as wheat, maize (corn), rye, spelt, barley, and sorghum; as well as spices (black pepper, mustard, etc.), pulses (lentils, etc.), and similar foods.

The roller mill is carefully designed considering each detail to meet high quality, hygiene, and safety standards.

HSRM Roller Mill is also equipped with Advanced Sensor Technology™ to ensure ultimate milling performance.

- Central lubrication system

- Quick roll change mechanism

- Low energy consumption

- Quiet operation

- Main roll temperature monitoring

- Stainless steel contact surfaces