- Home

- Companies

- Sky Greens Canada

- Products

- Sky Greens - Rotating Vertical Farming ...

Sky Greens - Rotating Vertical Farming System

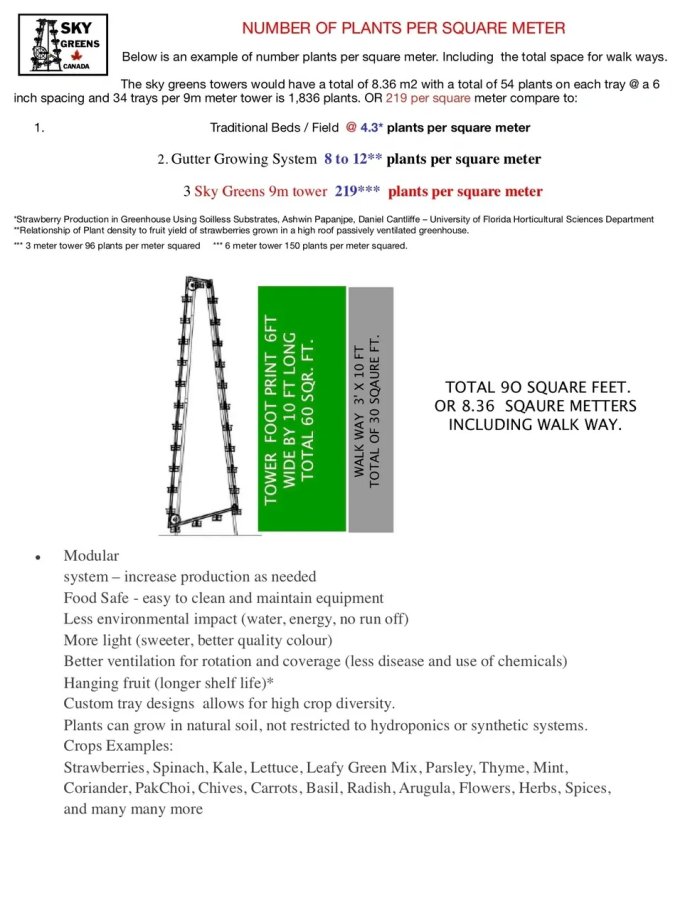

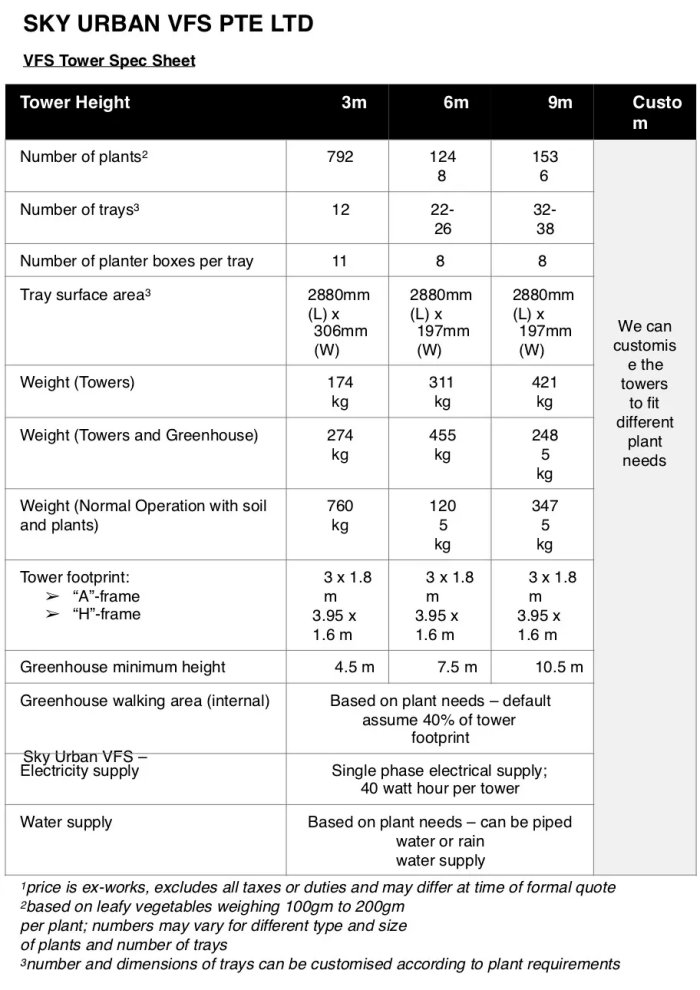

The demand for locally grown fruits and vegetables currently exceeds the supply readily available. By utilizing newer technology, we have the ability to grow a vast majority of our required fruits and vegetables locally ( limiting the need for importation). Sky Greens patented vertical farming systems consist of rotating tiers of growing troughs mounted on an A-shape aluminum frame. The frame comes in three different sizes: 3, 6, and 9 metres in height. It has the ability to house upto 38 tiers of growing troughs, which can accommodate the different growing mediums of soil or hydroponics. The troughs rotate around the aluminum frame to ensure that the plants receive uniform sunlight, irrigation, air flow and nutrients as they pass through different points in the structure.

High Yield - When compared with traditional monolayer farms, the Sky Greens patented vertical farming system intensifies land use and can result in at least 10 times more yield per unit land area.

High Quality - The structures are housed in a controlled environment which enables stringent control of input materials to bring about food supply, food safety, food security and food quality assurances.

High Flexble. Structures can be tailor-made to suit different crops, growing media and natural conditions, allowing cultivation on originally non-arable lands.

Low Energy Use - With the harnessing of natural sunlight, there is no need for artificial lighting. Rotation is powered by a unique patented hydraulic water-driven system which utilizes the momentum of flowing water and gravity to rotate the troughs. Only 40W of electricity (equivalent to one light bulb) is needed to power one 9 metre tower.

Low Water Use - With the plants irrigated and fertilized using a flooding method, there is no need for a sprinkler system thereby eliminating electricity wastage (as well as water wastage due to run-offs). Only 0.5 litres of water is required to rotate the 1.7 ton vertical structure. The water is contained in a enclosed reservoir system and is recycled/reused.

Low Maintenance - Being housed in a protected environment ensures that the system can be relatively maintenance-free and have low man-power dependency. The rotating troughs and intensified plant to plot ratio also means high man-power efficiency.ibility - Made of aluminium and steel, the modular structures are robust yet highly customizable and scala