Demir Packing & Agricultural Machinery

- Home

- Companies

- Demir Packing & Agricultural Machinery

- Products

- Demir - Round Baler & Wrapper

Demir - Round Baler & Wrapper

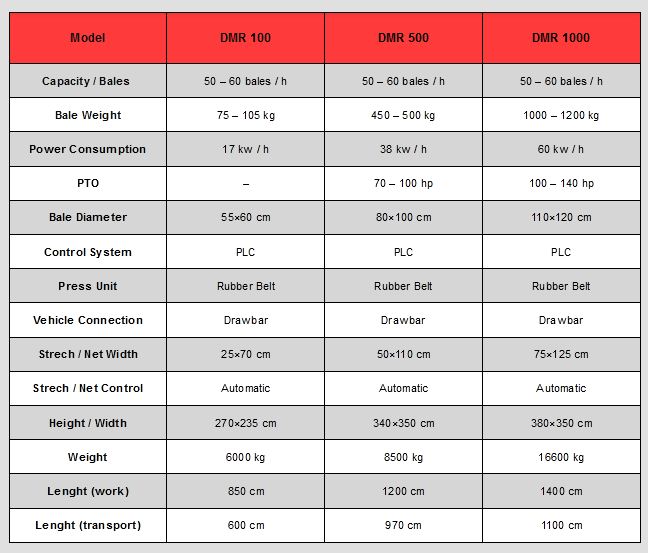

Best way to retain product’s freshness and preserve quality by wrapping harvested materials such as silage , pulp, sawdust, all roughage feeds etc. in range of 100; 500; 1000 kg. Our machines provide a significant contribution in the feeding animals by preserving materials’ longtime freshness if bale protected under appropriate conditions, protect its freshness long times and productivity so that the expenses stemming from animal feed is minimizedMost popular related searches

round baler

agriculture round bale wrapper

animal feed

animal feeding

silage wrapper

fruit pulp

automatic silage

corn silage

silage

bale transport

- Easy loaded and folding bunker submit easy material loading without to much labour.

- Speed adjustable conveyor transfers and mix materials to the press room and protect blockage in the throat of the press room.

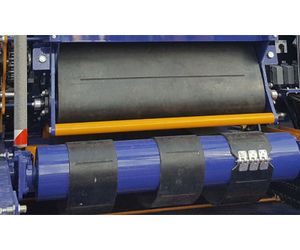

- Improved press room provide optimum press with rubber belt.

- Net wrapping unit help to protect of bale shapes by covering it by net. Works with hydromotor.

- Material recycling units help to transfer the materials, which fall out from press room or bale, to press room again.

- Bottom conveyor belt transfer the bale from bale room to strech wrapping unit.

- Double arm strech wrapping unit provide optimum wrapping to protect the materials from external factors.

- Wrapper system is proportional valve and can be operated at the desired speed. Works with hydraulic system

- All the bearings, chains and gears have automatic lubrication.

- Because of machine works with proportional system, there are double hydraulic pump and double cooler system

- Machine has remote control system.

- Machine can bale the materials as ; maize silage, beet pulp, fruit pulp, roughage and garbage.