Like all models in ZAGO’s KRAUSE series, the machine is equipped with a standard Tier 5 engine, but can also be supplied with a standard Tier 3 engine if required.

You can choose between different diesel engine powers for different materials to be processed.

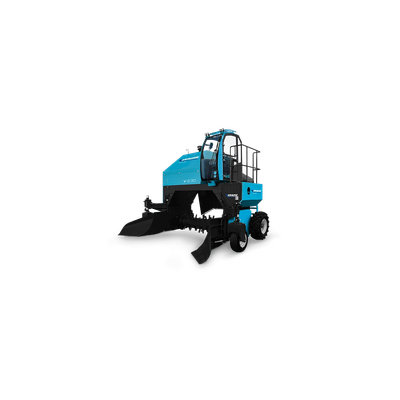

The line of KRAUSE – V self-propelled turners is characterised by its wide standard equipment and optional customised solutions.

Handling

KRAUSE 8.30 is characterised by a chassis with tyres, which is maintenance-free and provides good traction, even on unpaved surfaces.

Optionally available with rubber tracks.

The rear-wheel drive and front steering system allow 360° rotation on the machine’s axis, optimising the surface area required in the plant.

Wear-resistant rotor

The rotating rotor made of Hardox wear-resistant material is driven by V-belts, ensuring less loss of efficiency for the same performance.

Mechanical transmission

ZAGO’s unique mechanical drive translates into advantages that directly benefit the customer:

- Fuel savings

- Reduced emissions

- Less hydraulic oil

- Lower maintenance costs

The turner rotor is height-adjustable.

Maintenance

The machine requires little maintenance and therefore downtime is kept to a minimum.