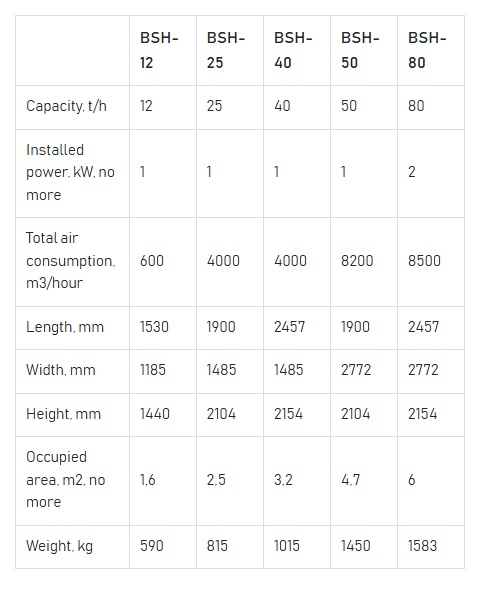

Sieve - Model BSH-12, BSH-25, BSH-40, BSH-50 & BSH-80 -Sieve Grain Cleaner for Separation and Cleaning

The BSH Sieve Grain Cleaner is a specialized machine engineered for the efficient cleaning of grains such as wheat, rye, and oats. This equipment is adept at removing impurities based on geometrical dimensions and aerodynamic properties. Integral to the operations of mills, elevators, and groat mills, the BSH grain cleaner is designed with several key components. These include a bed, a body with sieve frames, a balancing mechanism, and a sedimentation chamber, among others. A notable feature is its suspension system, where the body hangs from the bed on flexible hangers, facilitating more efficient operation. The BSH grain cleaner is available in various configurations, including options like an aspiration chamber, cyclone, and pre-cleaner. This flexibility ensures it can be tailored to meet specific industrial requirements and production conditions, making it a versatile tool in the grain cleaning process.

Separators of grain cleaning mark BSH are designed for cleaning grain (wheat, rye, oats, etc.) from impurities differing from it by geometrical dimensions and aerodynamic properties. Separators are installed as a part of technological schemes at mills, elevators and groat mills.

Grain separators consist of the following units: bed, body with sieve frames, traverse with balancing mechanism, sedimentation chamber, fan, fan drive, pneumatic channel, screws, feeder, outlet trays, and fence. The body is suspended from the bed on flexible hangers.

BSH grain cleaners are available in various configurations, including aspiration chamber, cyclone, pre-cleaner and many other options. This allows our customers to choose the configuration that best suits their needs and production conditions.