Zanin - Single Step Hulling System

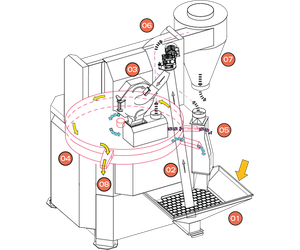

The product is fed by way of gravity into a feed auger to enter the hulling system, where it is shelled through a centrifugal action.

The product then passes through a perforated basket, which varies depending on the type of product being treated, before exiting the hulling unit.

The aspiration system at the exit separates the light part (gluma) from the grain, which is then sent to an oscillating separation system.

This system is designed to separate the clean product, which exits from the outer part of the plate, and the impurities, which are expelled, falling into the central part and returning to the feed auger.

Key

Product in infeed from huller

Product in infeed from huller

Hulled product

Hulled product

Light impurities

Light impurities

Recirculated product

Recirculated product

Breakage

Breakage

1. Product feed hopper

2. Feed auger

3. Huller

4. Oscillating plate

5. Broken product outlet

6. Aspiration

7. Cyclone

8. Hulled product outlet

- Tubular supporting frame with reinforcement profiles.

- Tubular casing with protective panels.

- Ballast with concrete plates.

- Tubular feed auger.

- Magnetic separator for product in outfeed from feed auger.

- Huller rotor.

- Product discharge box with extractor.

- Oscillating plate in carbon steel with mesh sieve.

- Control panel complete with inverter.

- Decanting cyclone

Available in various sizes and models for capacities from 400 to 900 t/h (capacities refer to incoming product. Calculated with spelt wheat. RH 14%, clean product. Specific product weight 0.60 t/m3).