- Home

- Companies

- ASM Assembly Systems GmbH & Co. KG

- Products

- SIPLACE - Model TX - Placement Modules

SIPLACE - Model TX -Placement Modules

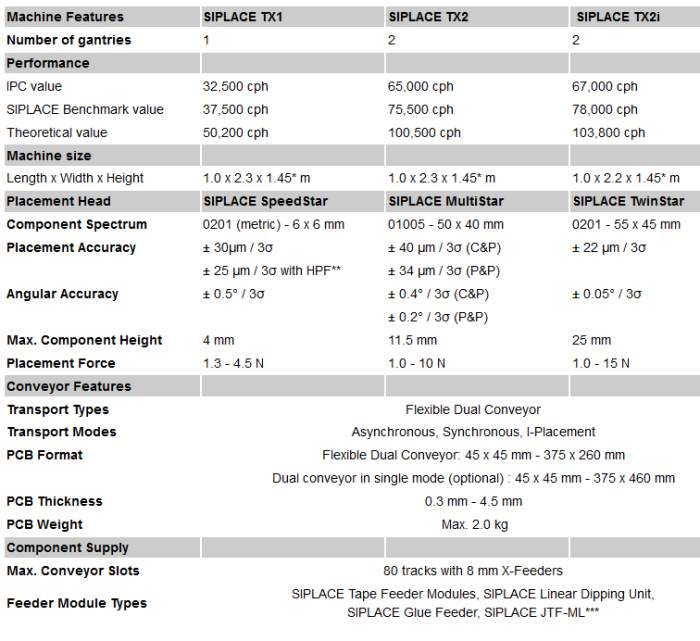

The SIPLACE TX placement modules are the new standard in high-volume production. No other placement solution features this level of precision (22 µm at 3 sigma) and speed (up to 78,000 cph) in such a tiny footprint (only 1 m x 2.3 m). For the first time you can place the new generation of smallest components (0201 metric) at full speed like any others.

The single- and dual-gantry machines, which are only 1 meter wide (approx. 3.3 feet) are flexibly scalable in the line. And the new and improved generation of the SIPLACE SpeedStar placement head delivers high performance and maximum precision at all times. In concert with the SIPLACE MultiStar and SIPLACE TwinStar heads you can cover a huge spectrum of components.

Programmed with the SIPLACE Software Suite and equipped with matching feeder options and our dual conveyor, the SIPLACE TX placement modules support efficient high-volume production, non-stop setup changeovers and state-of-the-art production concepts.

- Maximum placement performance and floorspace productivity

Up to 78,000 cph in only 2.3 square meters (approx. 25 sq.ft.) of floorspace - Maximum precision

It places 0201(m) components at full speed Placement accuracy:

22 µm @ 3 sigma - The improved SIPLACE SpeedStar

For sustained speed and precision - SIPLACE Multistar

The world`s only placement head that can switch on demand between collect-and-place, pick-and-place and mixed modes. - SIPLACE Software

Having the right software makes the difference in electronics production. - Standard dual conveyor

For flexible manufacturing concepts (synchronous, asynchronous) - State-of-the-art feeder options

Examples include the intelligent SIPLACE X feeders and the latest sensation in industry, tapeless feeding with the SIPLACE BulkFeeder - SIPLACE Vision System

One component, one image – the unerring high-resolution control system for maximum process reliability