- Home

- Companies

- Miller - CNH Industrial America LLC

- Products

- Intellispray - Spray-Air Technology for ...

Intellispray - Spray-Air Technology for Precision Crop Spraying

Miller STN's Spray-Air Technology is designed to ensure precise application of pest control substances, such as herbicides, fungicides, and insecticides. Leveraging an advanced air nozzle spray system, it allows the user to control droplet size, spray patterns, and the speed of air blast directly. This system ensures deep penetration into the crop canopy, leading to effective top-to-bottom leaf coverage, thereby enhancing crop protection. Spray-Air technology is integrated into Nitro and Condor series with spray widths reaching up to 120 feet. This system encourages efficient water usage between 2 to 10 gallons per acre, depending on the type of chemical applied. The technology encompasses the Dial-A-Drop™ feature for maintaining uniform application regardless of speed or pressure alterations. Users can choose between Spray-Air Air Nozzles for optimal efficiency, conventional flat fan nozzles for higher volumes, or a combination for maximal coverage. Operators benefit from reduced chemical usage, enhanced environmental stewardship, and notable savings in application costs.The most precise application technology available

When coverage is critical and you need deep canopy penetration to kill the target pest - be it weed, disease, or insect - look no further than to Miller’s Spray-Air air boom technology.

The unique air nozzle spray system puts instantaneous control of droplet size, spray pattern, and the speed of the air blast spraying into the crop right at your fingertips. There is no other technology available that will give you coverage as good as this, with the lowest application rates possible.

Available on the Nitro 5000 & 6000 series and Condor GC series with spray widths up to 120 feet. Spray-Air air boom technology will improve your application efficiency and generate a superior return on your investment!

How the Spray-Air technology works

• The Air Nozzles, spaced every 10” along the air boom, atomizes the spray droplets using Dial-A-Drop™ technology. This creates the optimum-sized droplets that are not affected by speed and pressure changes, ensuring a uniform application over the entire field.

• The Air Nozzle blasts the spray droplets deep into the crop canopy, ensuring complete top-to-bottom leaf surface coverage. No other application technology can measure up to the total plant coverage from the Spray-Air nozzle.

• Because of the smaller controlled droplets and directed air blast, the Air Nozzle allows for a very efficient use of water, often in the range of 2 to 5 gallons per acre for herbicides, and generally from 5 to 10 GPA with fungicides.

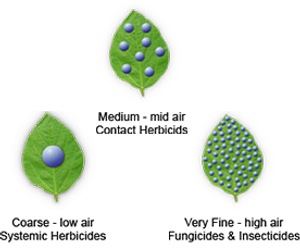

Droplet Size Management

Follow the ASAE Droplet Classification Standard with Dial-A-Drop™ technology.

Benefits of using Spray-Air technology*

• Maximize Productivity. The superior plant coverage from the use of the Air Shear Nozzle enables you to use only the minimum amount of herbicide required, and no more.

• Lowest Water Volumes. Use the lowest possible carrier volumes for herbicide, desiccant, insecticide, and especially fungicide applications. Spray from 2 to 10 gallons per acre.

• Fungicide Applications That Work. Simply stated, the Spray-Air technology is proven to be the best method to apply fungicides for superior disease control! Benefit from dense canopy penetration and total plant coverage with often only 5 to 10 gallons of water per acre!

• Application Versatility. Three application methods to choose from:

• Spray-Air Air Nozzle application to maximize coverage and efficiency

• Conventional flat fan nozzles for higher volume applications over 10 gallons per acre

• Use conventional nozzles + air blast from the Air Nozzle for classic Air Assist to maximize coverage in higher volume applications

• Environmental Stewardship. Spray-Air owners practice environmental stewardship by using only as much chemical and water as required, reducing soil and water carryover of crop protection products.

• Return on Investment. Operator surveys show $6 to $10 per acre in application cost savings