- Home

- Companies

- LP Stingray

- Products

- LP Stingray - Stingray Aquaculture Net ...

LP Stingray - Stingray Aquaculture Net Cleaner

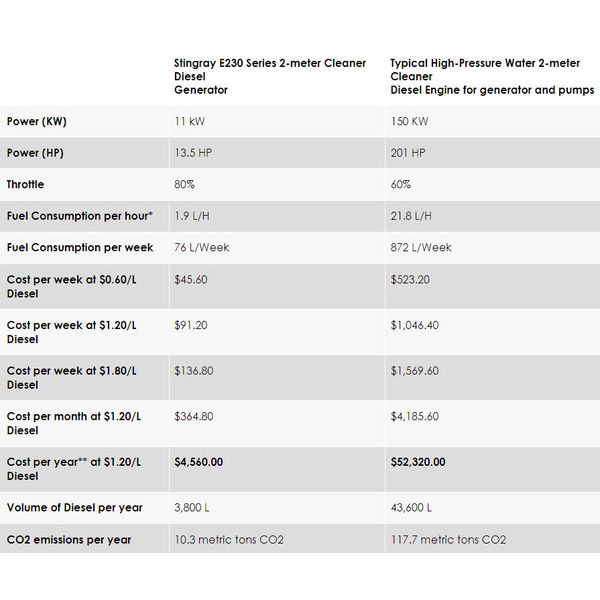

The Stingray aquaculture net cleaner, developed by Lindgren-Pitman Inc, serves the aquaculture industry by efficiently cleaning fouled net pens. This innovative and patented machine is designed to lower operational costs, minimize maintenance, reduce CO2 emissions, improve the welfare of fish, and enhance safety without causing damage to the nets. Initial research highlighted that traditional high-pressure water cleaners were inefficient, resulting in over 80% power losses and ineffective removal of mussels, shells, and kelp. The Stingray incorporates a specialized low-speed propeller designed by experts in nuclear submarine technology. This electric-driven propeller uses a raked blade to efficiently remove fouling through the net wall without damaging it. Additionally, the Safetrak system features a urethane rubber track with stainless-steel studs that engage the net and facilitate movement above the waterline. By pressing directly on the net and employing articulated knuckles to shake off fouling, the Stingray provides a net-safe and fish-friendly solution. The machine significantly reduces decibel noise levels, benefiting fish welfare, and cuts CO2 emissions by up to 90%. The 2-meter variant requires only an 11 kW generator, making it an energy-efficient and reliable option for maintaining healthy aquaculture environments.

Startup and Pre-work checklist is performed on deck

The E230 Series cleaning head is raised by crane from it's deck mount with personnel tending the umbilical. An 11 kW generator is mounted aft. A crew of two can run the whole operation.

Umbilical and Spool

The tough and durable umbilical protects wires and tube. A custom levelwind and fairlead ensures a perfect cable lay to prolong umbilical life and maintain a clear deck. Simple controls and safety measures are built-in.

Electrical enclosure and Remote controls

An 11 kW generator supplies AC electric power to the wall-mounted enclosure which powers the PLC controls, remote control, and sends AC power to the head. The remote control can display motor information, depth, direction, and live camera feeds. It also has a tough and durable cable flexible enough for the operator to walk on deck.

All electric operation means it cannot freeze.

Freezing conditions are not an issue!

Guards protect tracks and control loose net.

E230 Series head stowed on cradle. Shown ready to deploy

The cleaning head is positively pressurized with dry air. This allows for better hose flotation for travel on the net and most importantly safeguards the electronic components. The umbilical is connected directly to the cleaning head without tension.

Staff lowering head into the pen to clean

A convenient lift point for a crane hook allows for easy lifting and deployment of the cleaning head. Staff member overseeing deployment, 270 kg cleaning head weight.

Lowering head into the pen to clean

The cleaning head can be adjusted to positively or negatively buoyant. The umbilical is slightly positively buoyant. A gaff can help control the head through the lifting ring.

Remote hand-held corded control

The controller has an easy-to-use touchscreen and joystick controls. It is made for all-weather industrial use. A durable, flex-rated, UV- and chemical-resistant cord connects to the console. The video screen also displays navigational aids like depth and direction. Speeds, power, and depth are displayed on the control screen.

Four Cameras at each corner provide views of net ahead and behind

The wheelhouse screen provides a larger view of cameras.

On-site use with actual cleaning performance

Navigational indicators on the camera screen allow the operator to clean

efficiently and confidently. Movement is possible in many types of fouling and in any orientation.

Learning that offshore aquaculture net cleaning was one of the highest costs behind feed at and was a surprise and motivation for aquaculture net cleaning development at LP.

The Beginning

Research revealed that aquaculture net cleaning was normally done using high pressure water cleaners. Obviously cleaning aquaculture nets this way was inefficient with most of the power wasted in mechanical, viscous, and turbulent losses that calculate at over 80% losses. But if you don't mind the maintenance and fuel cost, and nothing else is available it's OK. Furthermore, it is not very good at taking off mussels, shells, and kelp necessary for good aquaculture net husbandry. Moving the aquaculture net cleaner around with thrusters was a first try we but found it to be inefficient. Tracks to move aquaculture net cleaners were not new but had a poor reputation and if adequate features were added to improve performance netting could be torn. And none of the current technology would clean the water line.

Lindgren-Pitman has several engineers with the creativity and resources for R&D. However, there is no offshore farming in south Florida to do testing. Testing of ideas on fouled nets started in a quarry In the Florida Keys dug by Henry Flagler of Standard Oil while building the railway to Key West. There was no permit necessary to install the net required, but it was populated with lemon sharks among other fish. A long list of ideas failed but generated more ideas. Later testing was done on salmon farms in Washington State and the net friendly Safetrak testing was done initially in the president’s swimming pool prior to testing on farms. It all took years of dedicated work.

To remove fouling we press directly on the net with a special low speed propeller. It was designed by Greg Platzer from the team that designed the quiet nuclear submarine propeller. The electric driven propeller efficiently sucks fouling thru the aquaculture net wall using a raked blade that does not damage the net. On the perimeter are specially designed knuckles / cams that shake the net sufficiently to remove fouling without damage as the propeller sucks aquaculture fouling away.

Safetrack's net-safe design has a urethane rubber track with articulated stainless-steel studs to engage the net and propel the aquaculture net cleaner. The studs are mounted on a flexible rubber stump that will bend and allow the articulated stump to bend and release at a design force well below the force where it could damage the net. Yet it is stiff enough to pull the aquaculture net cleaner above the water line to clean.

The environment and fish welfare has been a focus of the industry and the public in recent years of the aquaculture industry. The Stingray electric aquaculture net cleaner reduces CO2 emissions by up to 90% compared to similar cleaners. The Stingray 2-meter uses only an 11 kW generator. (link to efficiency page) The stress of the fish from the high decibel noise of high-pressure cleaners is eliminated, as our quiet brushless DC motors do not produce noise that disrupt the fish.

The Stingray is a proven aquaculture net cleaner with multiple patents. The benefits of efficient energy use, low operational costs, and high reliability will be a great addition to the operation of maintaining healthy and profitable fish in aquaculture net pens. We look forward to our continued growth and working with current and future customers to offer the best aquaculture net cleaner for their specific needs