- Home

- Companies

- Henan Sinovo Machinery Engineering Co., ...

- Products

- SIMEC - Sugar Cane Bagasse Pellet Plant

SIMEC - Sugar Cane Bagasse Pellet Plant

Bagasse is the fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juice. As one of the main by-products, for each 10 tons of sugarcane crushed, 3 tonnes of bagasse is generated by the sugar factory.

A typical chemical analysis of bagasse might be (on a washed and dried basis):

- Cellulose 45–55%

- Hemicellulose 20–25%

- Lignin 18–24%

- Ash 1–4%

- Waxes <1%

Except for being used as the raw material for producing pulp, paper, board, the bagasse is often converted into pellets, which are used as fuel and cattle feed.

Bagasse Pellet Fuel

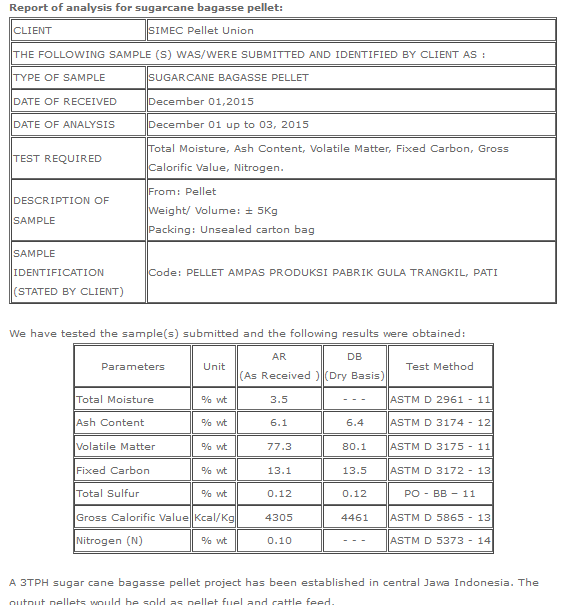

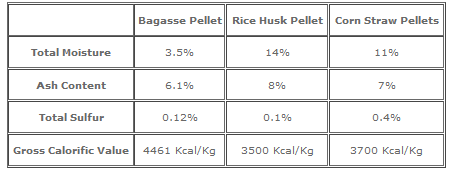

Bagasse pellets are treated as one of the main biomass energy in the biomass pellets market. Comparing with other biomass raw materials, the bagasse contains around 20% lignin, which can help the pellet forming. Meanwhile, the bagasse pellet has higher calorific value at 4461 kilocalorie per kilogram (kcal/kg) (or 4.5 kilowatt hours per kg), and lower ash content at less than 6.4%, compared with other biomass pellets.

The bagasse pellets can be used as the solid fuel for their own boilers of the sugar factories, or be exported to the target markets. In Southeast Asia, plenty of bagasse pellets are exported to South Korea as the co-firing fuel for the power plants. China has also started importing bagasse pellets in quantity for the consumption of the coastal biomass power plant. Each power plant can consume at least 10000 tonnes of pellets per month.