BDW Feedmill Systems GmbH & Co. KG

- Home

- Companies

- BDW Feedmill Systems GmbH & Co. KG

- Products

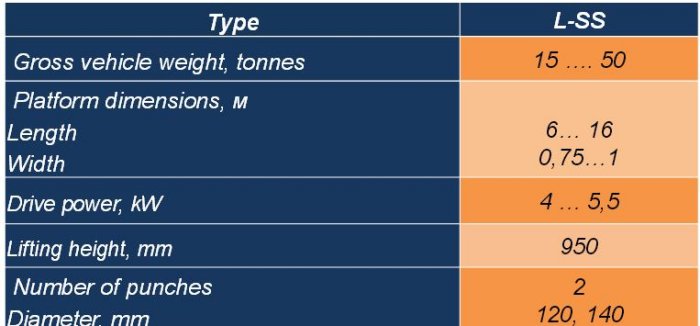

- Tipping Platforms

Tipping Platforms

Tipping platforms are used for unloading all bulk materials using different types of vehicles. The grain tipping platform is operated manually on-site through manual gear change.

Most popular related searches

- Electromagnetic control valves with dead man`s control and security interlock ensure easy and safe operation

- Crushing and shearing points are secured by rubber deflectors on the platform

- Different platform lengths and load capacities allow fast, uncomplicated unloading of all bulk materials with a wide variety of vehicles

- With high handling capacity, the use of double tilting platforms is recommended, since entire road trains or tractors with a trailer can be unloaded without uncoupling

- With the double tilting system, each platform can be operated individually

- The platform is directly connected to the hydraulic props, which can swivel towards the intake hopper. No etching takes place between the tires and the stage platform during tilting, since the platform automatically adjusts to the respective track width of the vehicle to be unloaded

- Automatic level control ensures smooth, torsion-free lifting of the vehicle, even in the event of uneven loading of the platform The drive unit with motor, switch valves, etc. is incorporated in the silo, hall or cellar instead of in the platform foundation, where it is exposed to moisture and high dust content. Even if the platform foundation is filled up with water, the tipping system remains functional. This is a vital contribution to operational safety