Tourmix - Model 03 DUO -Mobile Grain Plants

What´s the plan today - your customer demands a a 12 t large mixture, to different feed mixtures, or a 500 kg special mixture? The new TOURMIX 03 DUO will do it all. Because it is equipped with two mixing containers, two weighers, two filter units, and a large hybrid blower with a variable drive. two completely different mixtures can be simultaneously produced and discharged.

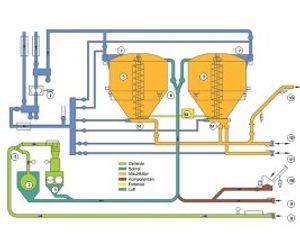

Possible modes of operation:

Combination mode: Both mixers are simultaneously and evenly loaded by a weight-operated oscillating flap, then the large mixing is discharged at one go. Two discharge lines provide double discharging performance.

Parallel mode: Processing of two different feed mixtures, with only once driving to and loading from the respective feed component storage. Simultaneous discharging of both mixtures to two feed silos.

Supply mode: Loading one mixer with a feed component or a pre-mixing, then processing the complete mixture inside the second mixer with simultaneous weight-controlled loading via shuttle valve from the supply mixer. Perfect solution for places where feed components to be mixed are beyond the range of the suction lines.

- Significantly better milling performance enables a more effective use of machinery

- Lower labour costs per ton of processed feed

- Halving of driving and manoeuvring time

- nConstant mixing accuracy of 1:100.000 for all sizes of mixture

- nSmall mixtures from 500 kg up are possibe without loss through residue inside the plant

- nSuction with full blower performance, but reduced mill revolutions

- nDischarging with engine idling, with full blower performance

- nLow learning curve for new staff because of the simple, self-explanatory operation via the graphical user interface

- nLarge, wide opening cover panels (zinc- and powder-coated) provide excellent access to all parts of the plant

- nStainless steel mixers without inner struts provide high mixing quality and optimum emptying of residue

- Suction flap

- Hammer mill

- Grain roller

- Hybrid blower with variable drive

- Suction-pressure-mixer

- Shuttle valve

- Filter unit

- Suction line

- Suction line direct

- Component hopper

- Discharge line right

- Discharge line left

- Discharge boom

- Blowout channel

Drive

- Direct drive by truck engine up to 350 kW

Blower

- Aerzener rotary lobe compressor Delta Hybrid, delivers up to 1,2 bar pressure

- Variable drive for blower revs, independent of engine revolutions *)

Suction line

- Diameter: 100 mm

- Max length 40 m

- Unique weight-operated oscillating flap

Mill

- Hammermill HF 400 with 72 hart metall hammers

- Screen cage with two screens

- Milling performance up to 30 t/h

Rolling unit

- Grain rolling unit GQ 64-2 with two powered, grooved rollers

- Squeezing performance up to 22 t/h

- pneumatic 4-position roller gap adjustment

Suction-pressure-mixers

- Capacity: 2 x 6 t (mixer volume of 10.500 l each)

- (smaller or larger on demand)

- Min. mixture 500 kg

- Mixing accuracy 1:100.000

- Max. low pressure: -0.7 bar

- Max. high pressure: +1,2 bar

- 2 filter units

- Large cleaning hatch in mixer cone *)

Emptying

- Diameter: 100 mm

- Max. length: 40 m

- Emptying performance up to 70 t/h

Control

- Controlled by TWIN-Control

- LCD colour display at operator´s position

Chassis

- 32 t permissible total weight

- Four axle truck, 3 axles steered

- Three axle truck option on request