- Home

- Companies

- Baker-Rullman Manufacturing, Inc.

- Products

- Baker-Rullman - Triple-Pass Rotary Drum ...

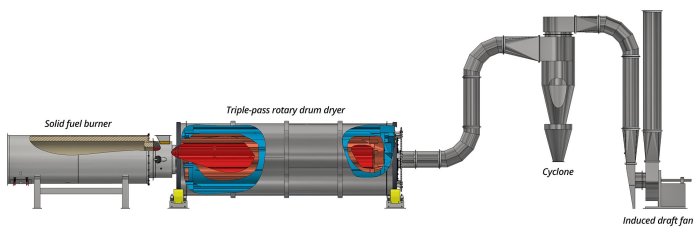

Baker-Rullman - Triple-Pass Rotary Drum Dryers

Baker-Rullman triple-pass rotary drum dryers have many product advantages over other drum dryer designs and have developed a reputation for performance and reliability. Baker-Rullman technology is known, accepted, and proven on six continents. Hundreds of Baker-Rullman dehydration systems are currently in service in more than fifty countries and in almost every U.S. state.

- Alfalfa

- Bakery waste

- Bananas

- Bone

- Brewer`s grains

- Manure, cattle & poultry

- Citrus pulp

- Coffee grounds

- Feather meal

- Forest products

- Fruit waste

- Grain by-products

- Hemp/CBD

- Humus

- Industrial waste

- Leafy drug plants

- Marine vegetation

- Meat packing by-products

- Paper pulp & sludge

- Rice

- Peat moss

- Potato moss

- Sawdust

- Seed corn

- Municipal sludge

- Sugar beet pulp

- Bagasse

- Tobacco

- Tomato pomace

- Vegetable waste

- Distiller`s grains

- Wet/dry miller`s by-products

- Wood chips

- Wafers & wood waste

Triple-pass dryer technology offers superior dehydration solutions by optimizing operating costs, efficiency, and product consistency.

The engineers at Baker-Rullman have developed and refined rotary drying through the years, demonstrating that the triple-pass design is the most reliable and proven technology available.

Step 1

Wet material enter the inner cylinder, propelled through the system via a hot gas air stream. The material is continuously lifted by the cylinder flights and showered through the concurrent stream of hot gases. The three full-length interlocked concentric cylinders rotate together design for the highest velocity in the inner-pass. As lighter particles quickly lose 60% of their moisture and move out of the cylinder, heavier/denser particles are retained until they also lose 60% of their moisture.

Step 2

Particles graduate to the next cylinder only when they have shed enough of their moisture to be carried out. Progressively larger diameters of the cylinders cause the velocity to decrease with each subsequent pass. In this section, the partially evaporated particles are handled more gently, again only graduating to the next pass when they have shed the proper amount of moisture.

Step 3

Because of the earlier retention time in the first two passes, material is relatively uniform by the time it makes it into the gentle third pass. This means the product is guarded against over-drying or under-drying and ensures the optimum use of heat while producing a consistently high quality end product.

Our innovative triple-pass drum dryer design offers industry leading performance and efficiency in the smallest possible package size.

A properly sized and tuned drum dryer system suited to your input volume is the key to planning an efficient system. Baker-Rullman`s specialized engineers are dedicated to accomplishing these goals with each and every installation.

Equipment Advantages

Baker-Rullman`s energy efficient, high-performance rotary dryers have developed a global reputation in ultimate reliability. Here are some key factors that have contributed to this unequaled record of dependable equipment:

Full Length Cylinders

All three cylinders in the Baker-Rullman triple-pass dryer system are full-length giving the customer the maximum effective length and residence time in the smallest possible package.

Drive Components

The drum dryer drive arrangement uses engineering class bushed roller chain and sprockets, specifically designed for this type of drive application.

Trunnion Rollers

Our trunnion rollers are made from Class 50 cast iron with a minimum roller face hardness of 270 BHN. The inboard tapered roller bearings, which have a `B-1-` life of 15 years, allow the roller to rotate around our stationary roller shaft supported by our hold-down pillow blocks. Baker-Rullman has proven this to be more reliable than the smaller diameter roller with an integral cast shaft system that is offered by our competition.

Drum Tires

Baker-Rullman drum tires are designed and manufactured significantly different from those used by other vendors. Each tire is hot forged from a single billet of AISI 1025 steel, then finish machined. There is no weld seam on it, and the steel grain structure is oriented for greater wear resistance and strength. It is forged into a "T" cross-section instead of the usual rectangular bar cross-section other vendors generally supply using rolled and welded bar stock.

Product Advantages

Baker-Rullman`s triple-pass dryer design remains the most trusted dehydration technology for optimizing operating costs, efficiency, and product consistency.

Lower operating costs

Baker-Rullman rotary drum dryers use less fuel per ton of product than many other drum dryers and do so in significantly less space. The triple-pass design provides approximately three feet of horizontal material travel for every foot of drum length. Precise electronic controls eliminate heat surges and fuel waste.

High BTU efficiency

Baker-Rullman triple-pass rotary drum dryer to achieve efficiencies better than 1,500 BTUs per pound of water evaporated. This is the result of better heat utilization created by longer residence times, robust temperature control, and superior drum insulation.

Consistent evaporation

Our triple pass dryer design protects your product from under or over drying. Heavier, wetter product moves slower than fine particles, giving uniform drying to all particles. That`s why our rotary dryers have long been known for protecting the protein value of food by-products and the integrity of all types of material.

Reduced V.O.C. emissions

V.O.C. (Volatile Organic Compounds) emissions can cause pollution problems and restrict your production rates. Heat utilization in a Baker-Rullman system is superior to that of the other rotary drum dryers by virtue of the triple-pass rotary dryer design, eliminating unnecessary V.O.C. emissions.