- Home

- Companies

- ISVE S.p.A.

- Products

- ISVE - Model IMP-VP - Vacuum Pressure ...

ISVE - Model IMP-VP -Vacuum Pressure Impregnation Systems

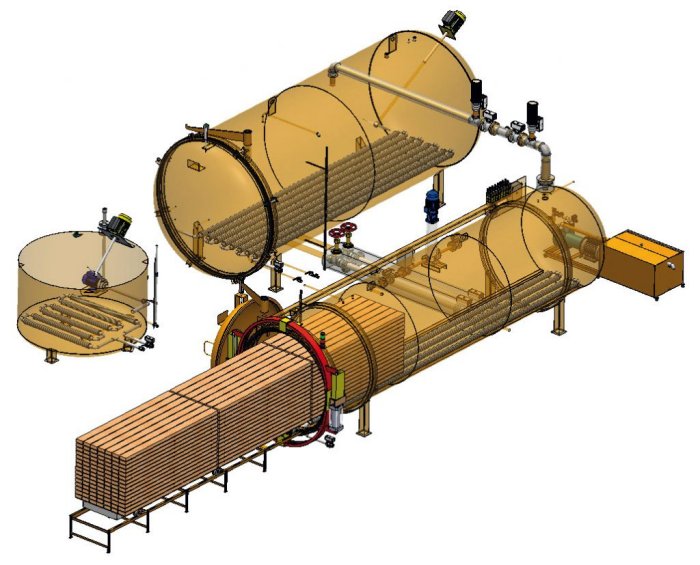

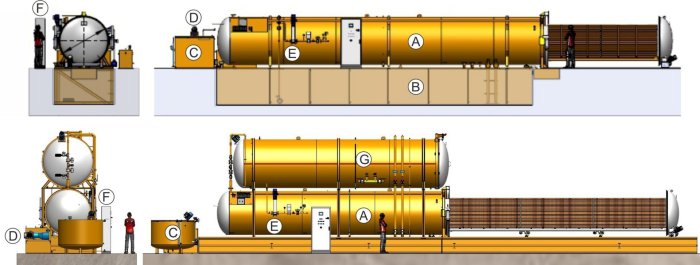

A standard plant is made up of:

- An autoclave capable of resisting a vacuum of -700mmHg at a pressure of 12 atm.

- Storage tank for the impregnant.

- A small sized preparation tank for the impregnant .

- A vacuum pump.

- A high-pressure pump.

- An electric switchboard panel with a microprocessor, with the possibility of connecting it to a personal computer.

- Should the plants be “off the ground” the possibility to go out to structure the plant with an autoclave positioned higher up that acts as a storage tank for the solution.

The reduced sizes compared to the productivity of these plants allow considerable savings in terms of space and they are easy to place inside the company.

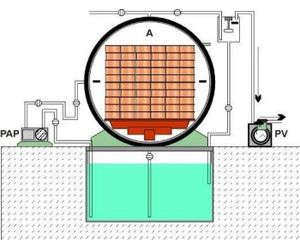

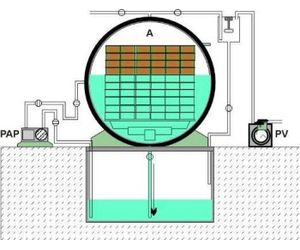

Phase 1: Initial Vacuum

The pile of wood, once positioned on the powered trolley of the autoclave, is placed inside the plant to start the cycle.

The hermetic closing of the door enables the machine to begin treatment by starting the vacuum pump. This phase, which is very important for the success of the cycle, frees the pores of the wood of air, by generating a “vacuum” which will allow the wood “to breathe” in the preserving solution. The length of the vacuum phase can vary from 30 to 90 minutes according to the characteristics of the wood.

Phase 2: Filling

Once the first phase is over, the vacuum is used to convey the treatment solution from the lower tank to the autoclave positioned above.

A level sensor that sends the plant computer a control signal controls the filling phase.

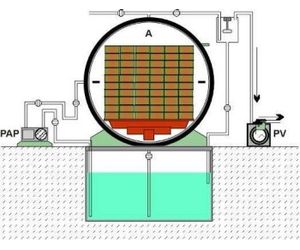

Phase 3 : Application of pressure

The third treatment phase has the important task of “forcing” the solution into the wood. The pressure pump may operate for from between 30 to 180 minutes depending on the characteristics of the wood. The combined action with the vacuum will enable the active principles to establish themselves deep in the wood thus guaranteeing long lasting protection.

Phase 4: Discharging the solution

On termination of the treatment phases, the solution not absorbed by the wood returns to the lower tank by means of a discharge valve positioned on the bottom of the autoclave.

Special automatic systems top up the salt contents and restore the level of the impregnant so that it is ready for a new cycle. All solution not absorbed is available for a new cycle without any waste.

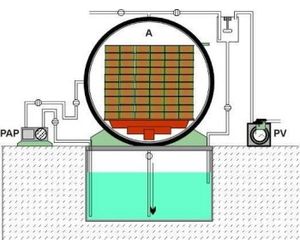

Phase 5: Recovery vacuum

A further vacuum phase lasting about 20-40 minutes facilitates the bonding of the active principles of the wood.

This phase is important in the “dripping” phase of the material being treated.

Phase 6: End of cycle

At the end of the impregnation cycle the autoclave returns to atmospheric pressure and the wood is ready for the following phases.

Duration of the process

The duration of the cycle varies depending on the following factors:

- Characteristics of the wood;

- Thickness

- Humidity

- Quantity and concentration of the salts required to be administered.

Complete protection of wood against degradation agents using pressure-vacuum technologyThe IMP-VP plants are suitable for treatment of items that fall into risk classes three, four and five.

The natural conformation of wood makes it unsuitable for use outdoors.

Its composition (20-30% lignin 40-50% cellulose, 20-24% carbohydrates) makes it vulnerable to “degradation agents” which begin their action when humidity is high and the temperature is between 10 and 40 °C.

Fungi, mildew and bacteria are in ideal conditions to develop, whereas the ultraviolet rays present in the sun light photochemically decompose the lignin making it soluble in water.

The only way to fight the action of the enemies of wood is turn to the help that modern chemistry provides.

As a matter of fact, if a good insecticide and fungicide is applied in sufficient quantity that also the internal parts of the wood are involved, the attack from micro organisms and insects can be offset for several years. Both the fungicide and the insecticide lose their effectiveness over the years, therefore the duration of the protection is directly proportional to the quantity applied.

An impregnant with a high level of dry residual can make the wood waterproof by protecting it from water until it is applied to form a surface film.

The pigments, which are not transparent, form an impermeable surface barrier against ultraviolet rays, thus preventing the decomposition of the lignin.

The traditional systems of dipping, brush painting and spraying are not able to guarantee to achieve the three results.

A product with a high dry residue level will form a surface film, limiting the penetration of the insecticide and fungicide solution.

On the contrary, a product with a low dry residue level will have better penetration allowing the insecticide and fungicide solution to be more active, but having very little resistance to the penetration of humidity into the internal parts of the manufactured item.

Only the use of pressure-vacuum technology has enabled pigmentation products with high dry residue levels (12-30%) to be applied resulting in complete protection of the item.