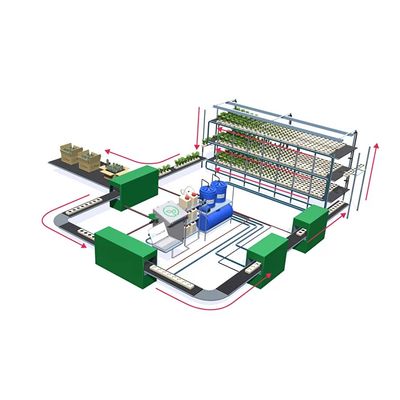

iFarm - Vertical Farming Automation Technology for StackGrow

Automated vertical farm system for energy-efficient cultivation of herbs and salads in a controlled environment

- Controlled-environment agriculture

- Commercial cultivation of leafy greens

- Fully-automated ready-to-use farming system

- No employees needed in growing area

Agribusiness

Ensure year-round hyperlocal production

Hospitality business

Ultra-fresh, premium-quality salads and herbs from the farm in your basement

Innovative startups

Game-changing technology that fits most innovation support programs and grants

Retail

IGS solution for a secure supply chain and longer sales period

- automated processes

- automation/mechanization of processes with the help of third-party equipment is possible

- available crop assortment

- 80 varieties of salads and herbs

- moving growing trays with plants inside the growing rooms

- phyto lighting

- mixing nutrient solution

- irrigation with constant control of solution’s EC and pH levels

- maintaining optimal climatic parameters

- maintaining the correct CO2 level

- substrate preparation

- sowing

- harvesting

- cutting and packaging produce

- disinfecting of equipment and rooms

- equipment maintenance

- disinfecting of equipment and rooms

- equipment maintenance

Always-fresh produce

Vertical farms can be situated in urban areas so that produce can be delivered to retailers and consumers when it`s at its freshest

Pesticide-free

The closed air cycle and controlled microclimate inside the farm avoid the use of non-biological pesticides, herbicides and acaricides

Fast scaling

Farms can be built in any configuration from 500 to more than 20 000 sq.m. It takes just weeks to design, build, and start growing

Saving space

Vertical tiers maximize space. With no need for soil, farms can be installed in industrial premises, warehouses and workshops

Environmental friendliness

Short supply chains drastically reduce carbon footprints, and controlled environment agriculture methods don`t impact the ecology

Cost savings

Production, processing, warehousing and storage in one location cuts expenditure. With iFarm Growtune software, no highly-qualified employees are needed

Easy cultivation

Process automation and farm management software reduces the risks of a vertical farming business and maximizes yields

Water saving

iFarm vertical farms consume 90-95% less water than traditional agriculture and translucent greenhouses