Wangen GmbH

- Home

- Companies

- Wangen GmbH

- Products

- Wangen - Model KL-RF - Hygienic Hopper ...

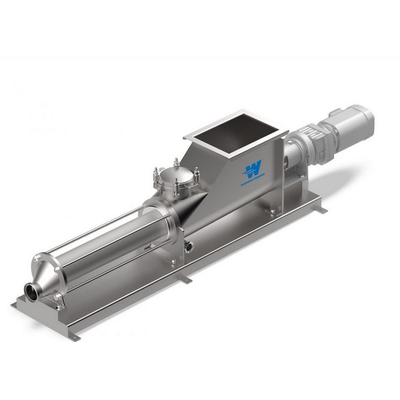

Wangen - Model KL-RF -Hygienic Hopper Feed Pump

FromWangen GmbH

The hygienic hopper feed pumps of the series WANGEN KL-RF have an inspection cover, a maintenance-free mechanical seal, which is independent of the rotation direction, and the dis-charge nozzle has a self-emptying design. The KL-RF is available with different rotor/stator geometric forms (S-, L- and H shapes).

Most popular related searches

- low maintenance

- rational and functional design

- gentle pumping

- optionally with heating or cooling jackets

- compact design

- long service life

- low Life Cycle Costs

- easy, space-saving assembly

- quick and easy manual cleaning

- excellent price/performance ratio

With the hygienic WANGEN KL-RF pump products are pumped in a particularly gentle way and can be optionally heated or cooled. A strength of the KL-RF is its use in plasticising blocks of fat or butter. Upon request, feed aggregates are also possible in special designs, as well as a version with an extension funnel.

- loading

- conveying media

- inspection port

- service-proven sealing systems

- maintenance-free mechanical seal independent of the sense of rotation

- various rotor/stator geometries (S, L and H geometry)

- stator with s-cone inlet for optimum filling of the pumping chamber

- easy cleaning thanks to construction with little dead space

- encapsulated mechanical seal, single or double acting, rinsed by the product

- materials with FDA certificate on request

- special feed unit versions possible

- enlargement possible with add-on funnel

- discharge flange with self-emptying design

- CIP (Cleaning in Place)

- robust bearing pedestal for high force transduction

- robust bearing pedestal with close-coupled drive and self-centering of the drive

- driven by a low-maintenance helical geared motor

- specially designed joints

- large variety of flange connections

- Stator with S-cone inlet for optimum filling of the pumping chamber

- various rotor/stator geometries (S, L and H geometry)

- Mature, robust universal joints with extended service life; non-clogging; with or without prefeeding screw

- Various mechanical seals as standard versions

- Sturdy block housing for various gear flange fittings

- flexible drive selection