- Home

- Companies

- Yongming Machinery

- Products

- Yongming - Model KTF5-3000 - Sunflower ...

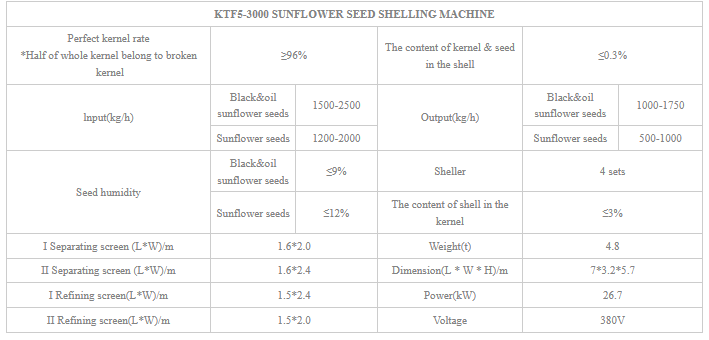

Yongming - Model KTF5-3000 -Sunflower Seed Shelling Machine

The highest perfect kernel rate and maximum yield capacity of sunflower and black oil sunflower seeds are ensured by systematic shelling procedures, non-crushing transportation, and efficient separating sieves assembly.

The KTF5-3000 Sunflower Seeds The KTF5-3000 Sunflower Seeds Shelling Machine is our patented product with the exclusive proprietary rights and having 80% of market share in China. The highest perfect kernel rate and maximum yield capacity of sunflower and black oil sunflower seeds are ensured by systematic shelling procedures, non-broken transportation, and efficient separating sieves assembly. The production begins with raw materials being fed in the dehullers and then shelled materials, the mixture consisting of kernels, husks and unshelled product is discharged to suspended separator. At this stage, a cyclone sucks and then removes hulls and dust, followed by separation of hulled kernels and unhulled seeds with vibrating screens. The unshelled seeds will be returned to dehullers. After passing of all of the stages, the finished product is ready and is deposited in the hopper. This product adopts bucket elevator to transport raw materials, which can avoid blockages effectively. Return processing system of non-broken hoist greatly reduces damages. Furthermore, the overall system of equipment is intelligentized with PLC electronically control system which is more efficient and convenient for regulation.

Higher capacity of shelling.

There is higher shelling capacity with two sets of shelling machine for raw material and returned materials shelling separately.

Lower broken kernel rate.

It will be decrease kernels broken basic on high yield of finished products through Raw materials elevating and returned materials elevating.

High selecting effect.

Suspended separator separate seeds and kernels efficiently.