- Home

- Companies

- Ag Leader Technology

- Software

- DirectCommand - Liquid Application

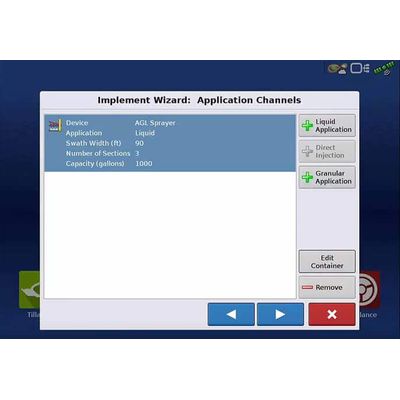

DirectCommand - Liquid Application

Get the application system that helps you apply effectively, mitigate risks and take control. AutoSwath, Variable Rate, Drift Monitoring, Crop Health Sensing, ISOBUS Compatibility.

Connect all your InCommand Displays whether working in the same field, different fields, or from one season to the next. Efficiency in your operation increases when you’re connected.

- Share guidance lines

- View as applied or coverage maps

- Sync machine configurations

- See live stats like container level or speed

Say Goodbye to Drift Concerns

Your drift concerns can be alleviated by prescribing the appropriate droplet size and alert you of potential for drift. Plus, your spray activity is automatically saved for peace of mind and reporting.

Weeds Can’t Escape

Dual-Flow Control For Consistent Coverage

Effectively eliminate with consistent coverage, even at the edge of a field or along waterways. In low-flow situations, the system automatically switches between flow-based control and pressure-based, calculating the desired rate to maintain consistent application.

Let Your Crops Tell You What They Need

OptRx Crop Sensors

If you are flat rate applying nitrogen late in the season, you may be over or under applying in certain areas of the field, impacting crop health and input costs.

OptRx crop sensors measure crop health and prescribe the exact amount of nitrogen needed on the fly.