- Home

- Companies

- WiseConn Engineering

- Software

- WiseFlow - Web-based Irrigation ...

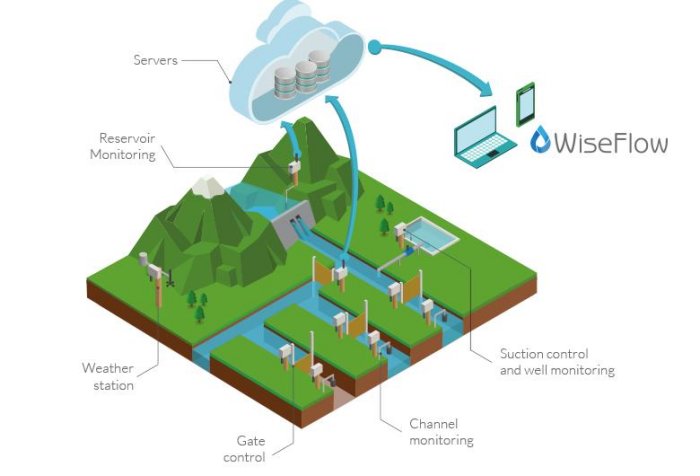

WiseFlow - Web-based Irrigation Monitoring, Control and Automation Solution

Get to know real-time information of canals, turnouts, rivers or reservoirs, using WiseFlow. A web-based solution for monitoring and controlling large water distribution systems.

- Dams, irrigations canals and floodgates monitoring and control

- Well monitoring and pump control

- Water quality monitoring

- Monitoring and control

Field nodes simultaneously monitor and control water delivery to your fields by controlling system components like gates, valves and turnouts. - Total water accountability

WiseFlow can automatically deliver the water data or changes to water flow or volume. - Information on the Go

WiseFlow can provide weather information, flow rates, water levels and pressure, and any sensor required by the irrigation district or water management entity. - Use your resources wisely

Automatic monitoring and control allows the workforce to focus on what really matters, replacing unreliable manual measurements. - Always Available

No IT and servers maintenance necessary - Historical data

Previous season records allows you to make better investments and management`s decisions, using the historical personalized farm data. - Warnings and alerts

Warning are triggered through SMS and/or email. - Map Display

Provide a birdseye view of your operation, showing real time water events.

Field sensors and actuators, deployed in specific points of the water distribution systems, communicate continuously through a mesh network, which connects to a web server using a gateway node. Users through their phone or web server log into WiseFlow to monitor and control flows ensuring proper distribution of water resources. Users in the control room log into the FluxClient software to take total control of the heap leach irrigation. Field sensors and actuators are deployed on each pad of the heap leach and communicate continuously through a mesh network, connecting to a remote server using a gateway node.