Begg Cousland Envirotec Limited

- Home

- Companies

- Begg Cousland Envirotec Limited

- Applications

- Filter solution for nitrogen ...

Filter solution for nitrogen fertilisers / ammonium nitrate – neutraliser & evaporator sector - Agriculture - Crop Cultivation

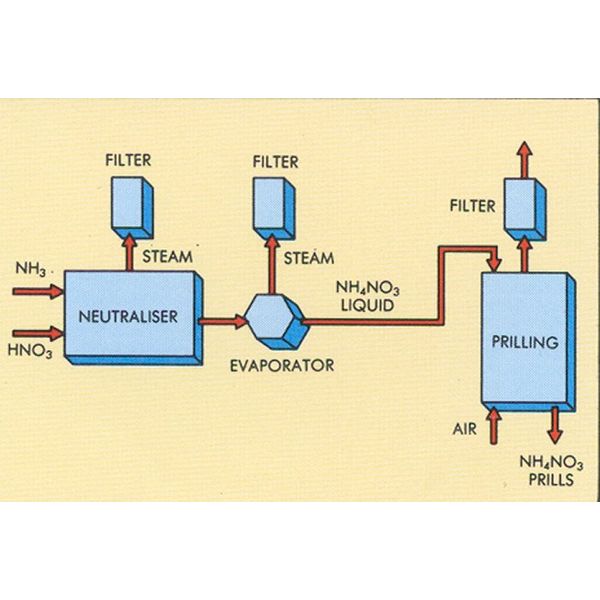

Process Information: Ammonia and Nitric Acid are fed to the Neutraliser, which can be operating under pressure, under vacuum or at atmospheric pressure. There is a high exothermic reaction which produces NH4NO3 and steam. Ammonium Nitrate solution is then fed to an Evaporator and the resultant concentrated solution goes to the Prilling Tower. NH4NO3 is entrained from both the Neutraliser and the Evaporator by the exiting steam, which can contain up to 15,000 mg/m3 ( or 4 kg/ton) of nitrate wSaveith an average size of 3 - 5 microns.

Most popular related searches

ammonium nitrate

agriculture crop

nitrogen fertilisation

nitrogen fertilizer

crop farming

ammonium nitrate fertilizer

fertilizer

cultivator

fertilizer nitrogen

nitrate fertilizer

Problems to Solve

- Air pollution.

- Intermediate (NH4NO3 solution), & thus final, product loss

Design Solutions

- Medium Velocity ‘Becofil’ Candle Filters, standing type F, with T80.35 Teflon Fibre elements and 304 Stainless Steel cylindrical structure.

- Medium Velocity ‘Becofil’ Panel Filters, type HTP, with T80.35 Teflon Fibre elements and 304 Stainless Steel frame structure.

Note: In case of long shutdown periods, the Candle Filter fibre should be washed with water to prevent damage.