Potato Deep Processing Articles & Analysis

12 articles found

As an important food and industrial raw material, the market demand for potato starch continues to rise, attracting numerous investors to enter this field. Before getting involved, calculating production costs and evaluating profit margins are crucial, and choosing high-quality processing equipment is the core prerequisite for achieving efficient profitability. As a leading enterprise in China's ...

We are welcomed by Maurice Hadders, potato grower in the countryside on the border between Flevoland and Friesland. The processing of potatoes is ongoing at full capacity, but luckily Maurice does have time to sit down and talk to us. We sit around a large round kitchen table, with coffee served in Boerenbond. We talk about the move to Schouten Optica CS. A deliberate and exciting choice, which ...

Potato agronomy is complex and requires a lot of planning, monitoring and evaluation throughout the production process. CPM finds out how digital agronomy tool Crop4Sight can help in all three areas as preparation for the 2023 season gathers paceIf you fail to prepare, you prepare to fail – an adage that is very relevant when thinking about potato crop establishment, with half the agronomy done ...

The potato chip production line is used to produce the familiar fried potato chips. The production line contains a series of potato chip processing machines. Potato chips making machine for the factory has many advantages such as convenient use and energy-saving and has been widely used in recent years. Many people who invest in potato chip production businesses need to use potato chip ...

A DT Dijkstra installation for potato processing will soon be installed at Stular in Naklo, Slovenia. During this project we will place a sorting, washing and bunker installation in a new hall. The project consists of a sorting line of 35 tons per hour and a washing installation of 30 tons per hour. In addition, a bunker installation is installed for interim ...

It is an important industrial raw material crop, a new energy crop and a natural feed crop. Deep processing of high-quality sweet potato starch into modified starch is a bright spot in the comprehensive development of sweet potato.Compared with the original starch, the starch deep processed by the modern ...

The starch material that has been dehydrated usually still contains a large amount of water. According to the nature of the starch material, the water content is generally between 35% and 45%. Dehydrated materials cannot be stored or transported for long periods of time. Drying is also a powdery shape, which has the characteristics of long drying time and not easy drying. In these cases, it is ...

1.Process 2.Production capacity Small-scale processing: 1.5-2 tons / hour, 3-4 tons / hour Medium-scale processing: 5-6 tons / hour, 6-8 tons / hour, 8-10 tons / hour Large-scale processing: 15-30 tons / hour The above processing amounts are based on the amount of processed fresh ...

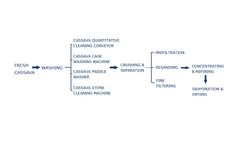

Sweet potato, also known as sweet potato, sweet potato, hawthorn, red glutinous rice, etc., is an excellent raw material for starch processing. The sweet potato starch production process is actually a physical separation process, which separates the cellulose, protein, inorganic salts and other substances in the raw materials from the starch. In the production process, starch is separated from ...

Minimal processing of vegetables has some undesirable physiological consequences. The shelf life of peeled raw potatoes is limited by the onset of enzymatic browning at the cut surfaces. It is generally accepted that polyphenol oxidase (PPO) is the enzyme mainly responsible for this type of browning. This work aimed to study the effect of vacuum storage at 4?C on the colour, which is the main ...

A potato processing factory in the north of England with a throughput of some 70,000 tons of potatoes p.a. was unable to meet its effluent discharge consent levels after increasing the variety and volume of items it prepared for retail sale. In August Cleveland Biotech was asked to review the factory’s effluent treatment system and to propose solutions. As a result of the additional ...

This paper critically assesses the potential and barriers for food system transformation from the conventional to an organic model by utilising the literature on system innovation. Based on the analysis of two food supply chains in the UK, namely chicken and potato production and processing, the paper demonstrates that the current conventional food system appears to be resilient to radical ...