- Home

- Companies

- Agromasters Ltd

- Products

Agromasters Ltd products

Milking Parlours - Milking Parlours for Cows

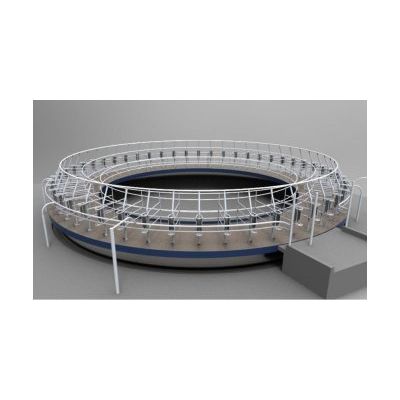

Agromasters - Rotary Milking Parlour

Rotary Milking platforms are renown for being the least labour intensive form of milking for medium to large herds.We manufacture and install Rotary Milking Platforms ranging in size from 24 to 100 cows. With rotation speeds variable from 6 to 11 minutes you can milk your herd quickly and efficiently. Rotary Milking Platforms use a constant flow process with the operator standing in one position applying the cups to the cows. The occasional cow that takes a little longer simply goes around twice and doesn’t hold up an entire row as in a typical herringbone dairy.

Agromasters - Herringbone Milking Parlour

The agromasters herringbone milking parlor combines advanced milking technology, but always with the lowest required investment. The milker sees clearly the 4 teats of the cow due to herringbone indexing of the animals. The ergonomic working position for the operator – ensures a comfortable milking job.

Agromasters - Herringbone Rapid Exit Milking Parlor

The Herringbone – Rapid Exit milking parlor is addressed to larger dairy farms. This type of milking system is designed to ensure comfortable animal positioning, high throughput & quick exit of the animals after the end of milking process . The elevation of the stall is achieved via the use of pneumatic cylinders.Animals are not pressed ( inside the parlour ) but only from the other cow that is following.

Agromasters - Parallel Milking Parlour

The Parallel milking parlour is another solution for the increasing needs of a modern dairy farm, with a large number of dairy cows. This type of milking system requires less space in terms of parlour capacity, since animals are positioned at 90°. Parallel parloursare equipped with a backward moving pneumatic system for bringing the animals towards the side of the milker .

Agromasters - Mobi-Master Milking Parlour

Agromasters mobile milking parlour is an ideal solution for farmers that move their herd in different locations during lactation period . Mobile parlor is specially designed for agromasters products.

Agromasters - Pipeline Milking System

Pipeline milking system is an ideal solution for an intermediate size cow farm. It is usually implemented when animals are kept tied in their cubicles and have to be milked at the place where they are standing. The milking is carried out using a portable milking unit which provides pulsation and delivers vacuum to the teat end. One milking station is usually installed for every two cows.

Milking Parlours - Milking Parlours for Goats

Agromasters - Model R-Master - Rotary Milking Parlour (Interior)

The R-Master Rotary is the type of Milking parlor with highest yields & with minimum required milkers (1-2) for its proper functioning no matter how big is the platform .

Agromasters - Model R-Master - Rotary Milking Parlour for Goats

The R-Master Rotary is the type of Milking parlor with highest yields & with minimum required milkers (1-2) for its proper functioning no matter how big is the platform .

Milking Equipment- Milk Receivers

Hector - Model 30 Litre - Glass Milk Receiver

The HECTOR I Glass Receiver is specially designed for RTS & goats milking installations. The 30 Litre receiver incorporates a unique design.Glass material enables the observation of milking and washing process. The upper and bottom lids are made of stainless steel and escorted with the necessary gaskets to ensure perfect foreclosure . Τhe central & downward base of the receiver is from Stainless steel and specially designed for this type of Receiver. The stainless steel sealing system allows the end user to empty the remaining quantity of milk .

Hector - Model 50 Litre - Glass Milk Receiver

The HECTOR II Glass Receiver has a capacity of 50 L . The glass material enables full observation of milking and washing process. This unique product is mainly used for cow milking parlours & bigger goat milking systems . The upper and bottom lids are from stainless steel and escorted with the necessary gaskets to ensure optimum foreclosure .The central & downward base of the receiver is made of Stainless steel and specially designed for this type of Receiver . The stainless steel sealing system allows the end user to empty the remaining quantity of milk .