BECO Dairy Automation Inc. products

BECO Automation

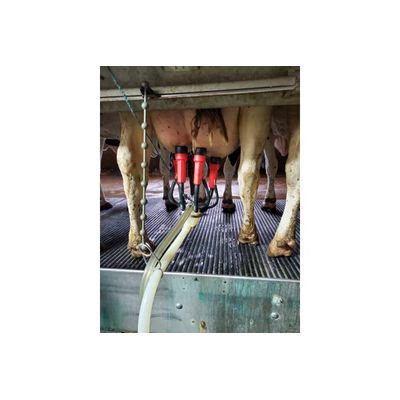

BECO - Model IMMIX G2 - Dairy Automation System

Milking performance and procedure information to assist in improved parlor management. Detacher settings are easily changed with a click of a mouse. Set maximum milk time for both automatic milking mode and manual milking mode. Real time information available at the computer. A BECO 7/8″ system will accept both 7/8″ and 3/4″ milk hose for maximum milk quality benefits. Optional Grab-N-Go feature for vacuum models allowing the operator to attach units without touching a button.

BECO - Model FlowNexus G2 - Parlor Monitoring System

FlowNexus G2 is a very smart automatic take-off. It has a full color display that gives you vital information about the milking process. The bright “no milk” and “manual” lights on the side can be seen far down the milking pit. FlowNexus G2 is designed to capture vital information on how a cow is being milked out and sends data to a computer where management can get a complete picture of the milking process. FlowNexus G2 can work with a standard BECO milk flow sensor and at any time you can add the BECO ScanNexus G2 milk meter and automatic cow ID for complete milk weight management.

BECO - Model ScanNexus G2 - Parlor Monitoring System

ScanNexus G2 is a highly advanced milk meter that is built around 21st century technology, making it the most advanced milk meter on the market.

BECO - Standalone Meter

BECO has designed our world class, industry leading ScanNexus G2 milk meter to be used as a standalone meter. The standalone meter allows for the meter to be paired with most any milking equipment, giving the dairyman accurate individual cow milk weights that are imported directly into their own herd management software. The meter just needs to be placed in the milk path. This option of the ScanNexus allows for the dairyman to manage their cows with individual milk weights without the high cost of replacing their entire milking system.

STALLS

BECO - Model 50-110 - BXR Rotary Stalls

The BECO BXR rotary is designed and engineered to withstand the rigors of a 24 hour dairy operation. The platform’s heavy duty construction and design maximizes milk quality and operator efficiency. From the CIP swivel to the raised deck, heavy duty construction, and properly aligned stalls, the BXR rotary was built with extreme detail given to strength, milk quality, and efficiency.

Milk Quality

BECO - Tango Liner

The Tango liner is a liner that incorporates two liner designs in one. Like the dance, the tango liner is a entanglement of two different things the Tango makes a much more productive liner. It is designed with the benefits of both a triangle liner and a round liner. The Tango’s barrel top half allows for faster milking while the lower portion transitions to give optimal teat health. The Tango liner will offer a long life rubber that will also provide the performance that you and your cows need. Allowing you to milk more cows in less time.

BECO H-FACTOR - Milking Claw

Provides steady claw vacuum that eliminates all claw vacuum restrictions. Stable claw vacuum improves milking by allowing maximum flow rates without disturbing claw and liner function. Plenty of capacity for today’s high flow rates. Large Capacity: 400 CC-7/8″, 350 CC-3/4″ Ergonomic design that milk harvest technicians like. 7/8 and 3/4 outlets available. Improves Unit Alignment Designed with wider forks for front quarters and narrow inlets for rear quarters allowing units to sit squarely under the udder. Strong, Light Weight, and Durable. Durable PPSU plastic (Radel®, Ultrason®) for strength and durability