- Home

- Companies

- DSL Systems Ltd.

- Software

DSL Systems Ltd. software

AutoPilot4Feed

Plan4Feed - Production and Truck Scheduling System

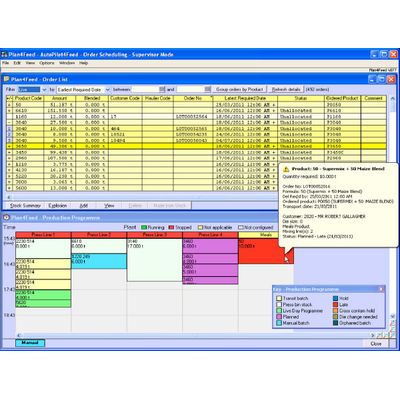

Plan4Feed is designed to simplify the process of scheduling orders for production. It does so by using a graphic display of the production programme and highlights any potential problems. Plan4Feed simplifies and speeds up scheduling and planning, it prevents scheduling mistakes, warns of orders which are going to be late and minimises flush batches and die changes.

OEE4Feed - Web Based Mill Performance Monitoring

OEE4Feed is a web-based reporting option for AutoPilot4Feed which enables users to monitor mill performance wherever they are. Users can view the OEE (Overall Equipment Effectiveness) metric and other KPIs from any period and make comparisons made between production lines and different shifts. Features include quality, availability, downtime analysis, energy usage, logistics and OEE monitoring.

Trace4Feed - Track Each Delivery (lot) for Feed and Grain Process Control Software

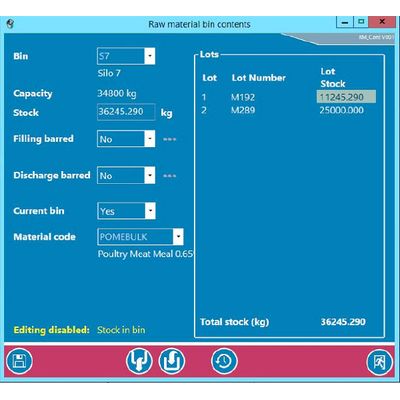

Trace4Feed is an option that enables the facility to track each delivery (lot) of all raw materials through the plant and into each delivery of the finished product. This includes bagged and bulk materials. Lots are tracked through bins on a first in, first out basis. With full lot traceability, the system can identify the products and customers, and trace the delivery of each raw material. In reverse, you can enter a particular finished product load and AutoPilot4Feed will display the raw material lots that went into it, enabling you to trace it back to the source. You can then use this to see if other customers are affected by any problems.

AutoPilot4Flour

MRP4Feed - Raw Material Requirements Planning

AutoPilot4Feed has a comprehensive option for material contracts, planning, purchasing and scheduling. MRP4Feed covers all the requirements for animal feed, pet food and similar plants. The system speeds up and organises material contracts, planning and delivery schedules and can even automate selected orders in a more efficient manner. Materials can be segregated into different groups so that bulk materials for instance, can be planned separately from premixes and medications. Materials can be specified with many default parameters such as default load size, lead time, preferred supplier, auto reorder level and so on in order to make planning simpler and faster.