- Home

- Companies

- EMVE Sweden AB

- Products

EMVE Sweden AB products

Machine Solutions - Intake & Storage

EMVE - Receiving Hoppers for Swift Unloading

Receiving hoppers for swift unloading from trucks or trailers. The versatile RH 2400 model enables efficient unloading through back tipping.

EMVE - Conveyor Hoppers

Hoppers for intake and storage in various sizes, handling capacities from 300 kg – 60 tons. Trevira: Hoppers using Trevira fabric bags for gentle handling and robust steel frames for reliability. Stainless Steel: Hoppers in stainless steel for storage before processing. These hoppers are mounted on variable-speed conveyors for easy flow adjustment.

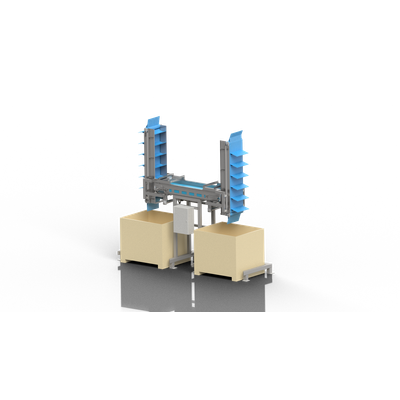

EMVE - Box & Bag Fillers

Designed for gentle handling and efficient filling of bags and boxes. Different models offer various features such as fall breakers, automatic conveyor reversal, and continuous operation to optimize filling processes, focusing on gentle handling and minimizing downtime during filling.

Washing and Grading System for Agricultural Produce

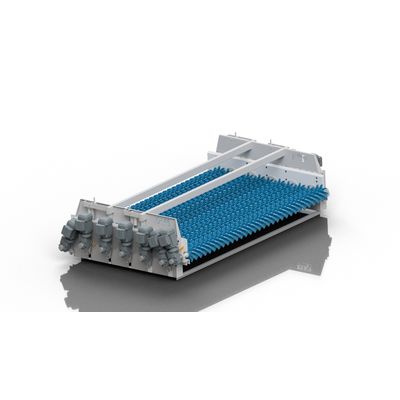

EMVE - Versatile Soil Extractors

Versatile soil extractors for different vegetables, capacity ranges from 1 to 80 t/h. Adjustable size for various items. Available in various widths and roller configurations to match different capacity and customer requirements.

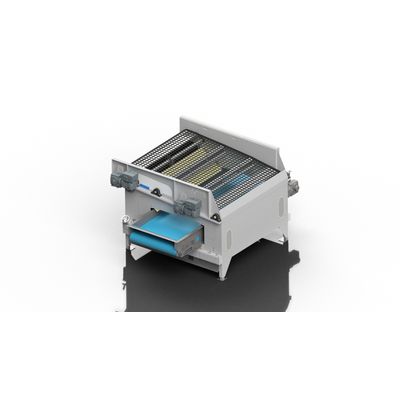

EMVE - Vegetable Sorting Roller Table

Rotating rollers turn products for inspection from all sides and ease manual sorting of potatoes, onions, root vegetables, etc. Adjustable table height ensures ergonomic work environment.

EMVE - Potato Graders

Our grading solutions (net, diabolic, roller, vibrating etc.) cater to diverse needs for sizing potatoes, onions, root vegetables, etc. Our versatile graders offer various lengths and widths, ensuring adaptability for different capacities and applications. Choose from multiple options to tailor to your specific requirements.

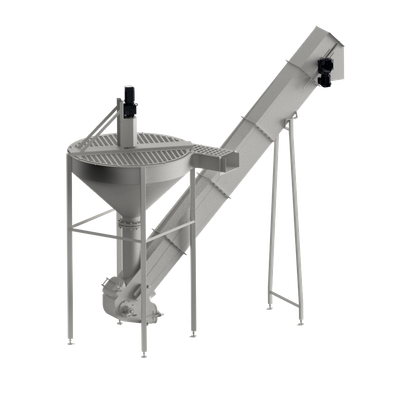

EMVE - Destoners

Water pressure allows the vegetables to float further down the line while stones are settled at the bottom, easily removed either through a manual opening or via the convenience of an automatic stone elevator, streamlining the cleaning process.

EMVE - Vegetable Stems and Roots Separator

Efficient removal of stems, roots, grass, etc. from various vegetables, offering capacities from 1-50 tons/h.

Machine Solutions - Pack & Palletizing

EMVE - Bag Filling Case Packer

Casepacker automates filling bags into boxes and crates at approx. 60 bags per minute, adaptable to bag type, product, and box. Folding up and control of handles, leveling shaker and printer are among a number of possible options.