- Transplanters - Row Planters - 1 Row Transplanter

- Transplanters - Row Planters - 2 Row Transplanter

- Transplanters - Row Planters - 3 Row Planter

- Transplanters - Row Planters - 4 Row Planter

- Transplanters - Vegetable Transplanter - Lettuce Transplanter

- Transplanters - Vegetable Transplanter - Tomato Transplanter

- Transplanters - Vegetable Transplanter - Potato Seed Planters

- Transplanters - Block Transplanters

- Seeders

- Automated Weeders

Ferrari Growtech S.P.A products

Transplanters - Row Planters - 1 Row Transplanter

Ferrari F-MAX - Automated Tray Transplanter Machine

Ferrari FMAX Evolution is ideal for transplanting various types of vegetables: brassicas, tomatoes, celery, fennel, tobacco, hemp and many others. This machine can be used for various types of modules: mainly conical, cylindrical and pyramidal It works without problems on any type of soil without requiring special processing and with qualified personnel it can exceed yields of 5,000 plants per row per hour. The machine is equipped with an intermittent 8 or 10-cups rotating distributor and a self-cleaning ploughshare that allow the plants to be placed exactly at the desired distance and depth. Ease of use, speed and extreme precision are the 3 reasons why thousands of farmers have chosen FMAX.

Ferrari Futura and Futura Twin - Automatic Transplanting Machine

This machine has been developed to have high-technology characteristics. It has been projected for the automatic transplanting of vegetables and tobacco stored in trays. It requires just one operator loading the trays into the charging slide of each single planting element. Each element of the machine is provided with a system, which automatically pulls out, from the longer side of the tray, the plants of the same row. These plants will be then taken from further movable grippers which supply the distributor.

Transplanters - Row Planters - 2 Row Transplanter

Ferrari Multipla - Mechanical Tray Transplanter

Ferrari Multipla is ideal for transplanting various types of vegetables: brassicas, tomatoes, celery, fennel, tobacco, hemp and many others, with mainly conical, cylindrical and pyramidal modules. MULTIPLA combines the same typical features and the high quality transplant of the brand Ferrari with the possibility of feeding a double row with a single operator; the productivity of the single operator is on average 3,500 plants / hour, with a maximum of 5,000 plants/ hour. The machine is equipped with an intermittent rotating distributor from 14 to 30 cups. according to the chosen version and a self-cleaning ploughshare that allow the plants to be placed exactly at the desired distance and depth. The parallel linkage on each single row guarantees maximum adherence to the ground and excellent work in any condition.

Ferrari - Model FPP EVO - Finger Transplanting Machine

Finger transplanting machine for plants in bare roots, cone, cylinder and pyramid sod (max diameter 5 cm [2"]). Row width is adjustable starting from min. 48 cm [17.7"] (25 cm [9.8"] tandem version). The min distance on the row is 6 cm [2.4"] (with 32 finger -Long chain).

Productivity: on average 2.800 plants/h - max 4.000 plants/h. Technical features: parallel linkage with front pneumatic wheel 0 470 mm - quick adjustment of planting depth -quick adjustment of the finger-ground distance -ploughshare for high-depth transplant (standard equipment). Fittings: electronic / hydraulic gearbox - telescopic frame -folding frame-watering applicator-water pipe stretching tool - fertilizer applicator - granular applicator -front disk.

Transplanters - Row Planters - 3 Row Planter

Ferrari FX and FX Multipla - Mechanical Tray Transplanter Machine

FERRARI FX is ideal for transplanting smaller conical, cylindrical or pyramidal modules up to a maximum height of 15 cm. This machine is born to solve the difficulties in transplanting the salad, like the narrowest spaces, thanks to the minimum inter-row spacing of 28 cm, but it works correctly also with all varieties of vegetables. The FX element is equipped with a parallel linkage that perfectly follows the deformities of the soil, clods or stones. The machine is equipped with a perimetral frame and has a roller in its standard version or traction wheels in the S version, designed for use on land with beds or for working with the need to use tractors with less power. FX has a maximum yield of 5,000 plants / hour per row and can be produced in a pulled or self-propelled version or with draw-bar.

Ferrari - Model FPA EVO, FPA Multipla and FP - Mechanical Transplanters Mulching Machine

Transplant onto mulched ground at maximum efficiency! Mechanical transplanter for transplanting on mulching film for plants in module (diameter from 2 to 5 cm) and square block (side from 3 to 5 cm).

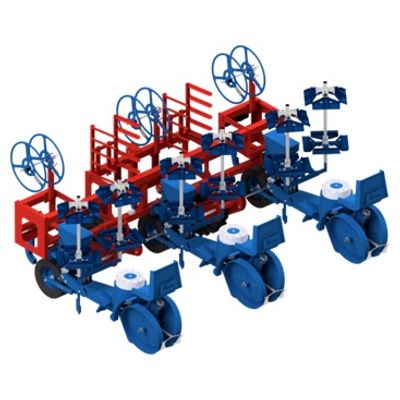

Transplanters - Row Planters - 4 Row Planter

Ferrari - Model F - Mechanical Transplanter Machine

The F Ferrari precision transplanter was designed to transplant lettuce and other vegetables in square blocks from 2.5 to 5 cm. This completely mechanical transplanter is extremely simple and easy to use. FERRARI F is very precise, every single unit is independent from the others and all the plant are left in the ground on a diamond pattern to guarantee a proper growing area to every single plant. F transplanter is equipped with a very narrow ploughshare and can work properly even on very difficult ground conditions. The transplanting machine output is up to 2,500 plants per hour per row. The machine can work either on flat ground or raised beds.

Ferrari Rotostrapp - Semi-Automatic Transplanter Machine for Seedlings

Absence of dead times and excellent positioning of the pLants are the main features of the Rotostrapp transplanter, available in hauled and self-propelled version. It only transplants the pressed-cube blocks with the side between 3 and 5 cm, with a minimum inter-row distance of 28 cm in line or "diamond", while the distance on the row is electronically adjustable from 10 to 100 cm. Working capacity varies up to a maximum of 8,000 plants / hour for each element, at a maximum speed of 2.5 km/h. The elements are all independent of each other thanks to the parallel Linkage and the planting is operated by a rotating system of separation and direct collocation, followed by an adequate covering. The self-propelled version also, with 2 or 4 driving wheels, is available with hydrostatic transmissions, power steering and hydraulic lifting; the automatic steering device allows not to use the driver. Transplant lettuces and vegetables to a height of less than 10 cm!

Transplanters - Vegetable Transplanter - Lettuce Transplanter

Ferrari FPA Flash - Mechanical Mulching Layer and Vegetable Transplanter

Mulching and transplanting in one step! Transplanting mulching machine for plants in module (diameter from 2 cm [0.8"] to 6 cm [2.4"]) and square block (side from 3 cm [1.2"] to 5 cm [2"]). Vegetables: tomato - lettuce - brassicas - celery - pepper - all other vegetables having leaves similar to the ones above listed with min height 6 cm (2.4") max 25 cm (9.8"). Operators: 1 each row. Versions: 3 point hitch. Frame: single bed. Minimum row spacing: 30 cm (11.8*) (34 cm [13.4"] with turning carousel). Performance h operator: on average 3,000 plants/h - maximum 5,000 plants/h. Main fittings: ploughshare for furrow opening - hydraulic transmission - stainless roller.

Ferrari - Model FPA Next and FPA Multipla Next - Mechanical Vegetable Transplanter

FPA Next-FPA Multipla Next Mechanical transplanter for transplanting on mulching film for plants in modules (diameter from 2 cm [0.8"] to 6 cm [2.4"]) Main features: Vegetables: tomato - lettuce - brassica -celery - pepper - all other vegetables with similar plants compared to the previous mentioned ones and with height min 6 cm max25cm. Operators: 1 each row (fpa next) - 1 each double-row (fpa multipla next). Versions: 3 point hitch. Frame: fix-telescopic. Minimum rowwidth:28cm(fpanext)-23 cm (fpa multipla next) . Performance h/operator: on average 3,000 plants/hour, maximum 6,000 plants/hour. Main fittings: parallelogram system -electronic gears –hydraulic transmission.