3 products found

Gentle Roll By EBM Manufacturing products

Gentle Roll - Screener for Multi-location Grain Screening

The Gentle Roll™ Mobile Screener is engineered for optimal mobility and versatility in grain separation and cleaning across multiple locations. Unlike the standard version, it offers enhanced options catering to specific needs and applications. Primarily used for the separation of mixed grains, its utility extends to cleaning grains such as barley, wheat, and soybeans. It accommodates customization as a standard feature, ensuring each machine meets the specific requirements of its user. The screener's performance is based on handling dry, free-flowing products with a bulk density of 720 kg/m3, achieving a capacity of 1900 cubic feet per hour per drum. Capacities may vary based on grain composition. The mobile model is constructed with high-quality materials to ensure durability and efficiency. It is suited for small to large capacities, with model variations available to fit diverse production scales and space constraints.

Gentle Roll - Grain Screener

The Gentle Roll™ Mobile Rental Screener is a versatile grain screening solution designed for easy transportation and use at multiple locations. This trailer-mounted unit can perform tasks such as separating mixed grains and cleaning grain efficiently. It features a capacity of up to 1,500 bushels per hour for grain cleaning, with mixed grain separation reaching 700-1,200 bushels per hour, depending on various mix factors. Constructed with top-quality materials, it maintains screening efficiency across different models, including a 9-inch model for smaller operations. The device is ideal for grains like barley, popcorn, wheat, soybeans, rice, corn, rye, and oats, and finds application in industries ranging from animal feed to wood pellets. Its robust construction and precise screening capabilities make it a reliable choice for those in need of efficient grain management solutions.

Gentle Roll - Grain Screening

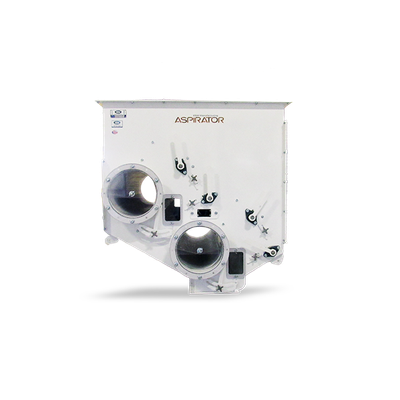

The EBM Aspirator is engineered to efficiently remove lightweight materials such as dust, chaff, hulls, and bees wings from grains, using a single-pass, closed-circuit air system. Designed for small grains including rice, wheat, barley, and oats, this aspirator improves product quality by separating out foreign materials that have similar size and shape but differ in density from the desired product. The system allows air to flow through the product at a calculated rate, creating a vortex that separates unwanted particles, which are then collected through a bag filter or cyclone. Its versatility allows it to be used in conjunction with existing systems, including the Gentle Roll™, or as a stand-alone solution. The design allows for easy adjustment of airflow to suit different grain characteristics, ensuring optimal separation efficiency. With a compact footprint, it fits seamlessly into new or existing processing lines, delivering reliable performance and enhanced product purity.