HALCO Software Systems Ltd. software

Other

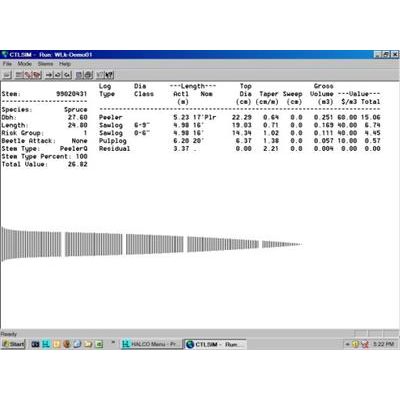

CTL-SIM - Cut-to-Length Harvesting Simulation Program Software

CTL-SIM is a comprehensive simulation program that allows accurate modeling of cut-to-length harvesting operations. By simulating accurately the cutting decisions of mechanical harvesters, improved harvest planning and equipment set-up decisions can be made. Different bucking rules can be applied depending on stem quality, for example to consider production of veneer peelers from high-quality stems. If cruiser-called grades are included in timber cruise information, the stem quality can be referenced directly. In cases where cruise data includes only general quality indicators, fractional yields of different stem qualities can be assumed.

LOGSIM - Log-Making Simulation Program Software

LOGSIM is a comprehensive log-making simulation program. Typically, the log products have grades which depend on log diameter and length, the extent of defects such as knots, scars, and on form characteristics such as sweep.

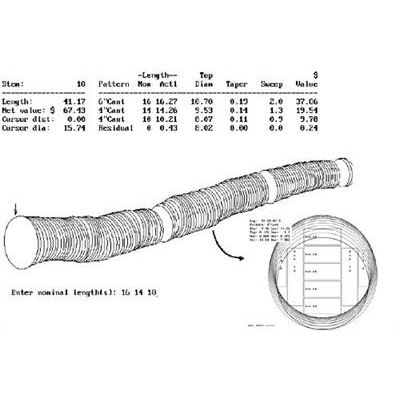

BUCKPRO - Bucking Improvement System

To help achieve the best performance many mills develop bucking rules for the cut-off saw operators. These rules are often in the form of a list, with the desired bucked lengths for different input lengths and diameters. Specification of these rules is a difficult exercise, as one tries to maximize value, recovery, and produce an acceptable product, particularly length, mix. BUCKPRO™ will help determine the optimum bucking "policy", or rules, for the mill.

Principal Software

WSO - Production Planning Optimization System

Optimize your production plan... Optimize your optimizers. Like most companies, you`ve invested millions in machine center optimizers throughout your mill. But does that mean your operations are truly optimal? In most cases the answer is no.

SAWSIM LP - Sawmill Production Planning and Optimization System

The SAWSIM LP system was developed to apply the power of SAWSIM and Linear Programming to sawmills, typically outside of North America, where a mix of a large number of products has to be cut to match a predefined product mix, usually from presorted logs.

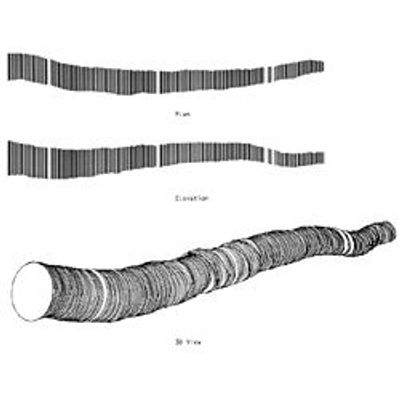

SAWSIM - Sawmill Simulation Program

SAWSIM is a flexible computer program that accurately models the breakdown of logs in any sawmill. With over 30 years of development, SAWSIM is widely recognized as the industry-standard sawmill simulation program. Using SAWSIM, virtually any question about sawmill operations can be answered. Typical applications include evaluation of mill design or modification proposals, alternative mill equipment options, and overall production planning and analysis. SAWSIM can process actual-shape logs with crook, sweep, ovality, and variable taper. Solutions are calculated individually for each log, based on its particular geometry. SAWSIM will print end view and 3d log plots, detailed results for each log that is sawn, and `Totals and Averages` to show results, including the overall lumber product distribution, for a distribution of logs that typically represent a complete shift`s production.

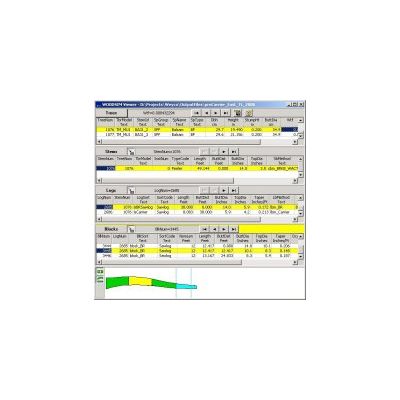

WOODSIM - Log-Supply Simulation Program

WOODSIM is a comprehensive program that simulates log-supply operations, from standing trees or long logs, through to bucked logs ready for sawing, peeling, chipping, or other manufacturing operations.

PANELSIM - Panel Mill Production Planning Optimization Software

PANELSIMis HALCO`s general name for a linear programming (LP) optimization model that may incorporate models of veneer, plywood, LVL, OSB, I-Joist, and stud operations. Any number of mills may be modeled either independently or together. An LP model resolves the trade-offs between yield, material flow, and manufacturing and material costs resulting from each operating alternative, to determine the operating plan that truly maximizes profit.