HRS Heat Exchangers Ltd. products

Heat Exchangers - Double Tube Heat Exchangers

HRS - Model DTA Series - Hygienic Double Tube Heat Exchangers

The HRS DTA Series is a complete stainless steel double tube heat exchanger designed for hygienic applications. The product flows through the inner tubes and the service fluid flows through the surrounding shell. Because of its geometry, the DTA Series is a true counter current heat exchanger. Using our corrugation technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised. Bellows are fitted to absorb differential expansion between shell and tube and multiple units can be interconnected for larger applications. Options include frame mounting, insulation and stainless steel cladding. HRS DTA Series is suitable for viscous products with large particulates in suspension. For high viscosity food products like honey, fruit jams and marmalades, please refer to our Annular Space and Scraped Surface Heat Exchangers product range.

Heat Exchangers - Multitube Heat Exchangers

HRS - Model MI Series - Hygienic Multitube Heat Exchanger

The HRS MI Series is complete stainless steel shell and tube heat exchanger designed for hygienic applications. The product flows through the interior tubes and the service fluid flows through the surrounding shell. The MI Series is an ideal heat exchanger for pasteurisation applications. Using HRS corrugation technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised.

HRS - Model MR Series - Hygienic Multitube Heat Exchangers With Removable Tubes

The HRS MR Series is a complete stainless steel shell and tube heat exchanger designed for hygienic applications. The product flows through both the inner tube and the surrounding shell for regeneration duties. The removable tubes allow hygienic processing on the shell side. The MR Series is an ideal heat exchanger for direct product-to-product heat recovery. Using HRS corrugation technology, heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, effects of fouling are minimised. Expansion bellows are fitted to absorb the differential expansion between the shell and the inner tubes. Multiple units can be interconnected for larger applications. Options include frame mounting, insulation and stainless steel cladding. The HRS MR Series is suitable for products with low to medium viscosities in hygienic applications.

HRS - Model MP Series - Multipass Multitube Heat Exchanger

The HRS MP Series is a complete stainless steel multitube heat exchanger, its design is ideal for hygienic and industrial applications. Using multiple passes on the tube side offers greater flexibility for optimising fluid velocity, pressure drop and heat transfer. The unique design creates longer thermal length within the same module, avoiding designs with multiple modules and interconnecting bends. Using HRS corrugation technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised. Expansions bellows are fitted to absorb the differential expansion between the shell and the inner tubes. Multiple units can be interconnected for larger applications. Options include frame mounting, insulation and stainless steel cladding. The HRS MP Series is suitable for applications which has low to medium viscosity fluids in food industry.

HRS - Model SH Series - Double Tubeplate Hygienic Heat Exchangers

The HRS SH Series is a multitube shell and tube heat exchanger designed with the added security of a double tubeplate, providing leak detection to avoid cross contamination between the service and product fluids. The HRS SH series is perfect for hygienic applications. Using our corrugation technology, heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised.

Heat Exchangers Annular Space - HRS AS Series

HRS - Model AS 3 Series - Annular Space Heat Exchangers

The HRS AS 3 Series is a fully stainless steel, triple tube heat exchanger designed for applications with viscous products. The product flows through the annular space and the service fluid flows through the inner and outer tubes to ensure even heating or cooling. The removable inner tube allows for easy inspection of the annular space. Using HRS’ corrugated tube technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised.

HRS - Model AS 4 Series - Annular Space Heat Exchangers

The HRS AS 4 Series is a complete stainless steel quadruple tube heat exchanger designed for applications with viscous fluids. The product flows through the annular space and the service fluid flows through the service tubes to ensure even heating or cooling. The removable inner tube allows for easy inspection of annular space. Using HRS’ corrugation technology, heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, effects of fouling are minimised. With the HRS AS 4 Series it is possible to offer designs with a high pressure on product side due to increased tube wall thickness. This makes it the ideal heat exchanger for very highly viscous food industry applications.

Heat Exchangers - Scraped Surface Heat Exchanger

HRS - Model Unicus Series - Reciprocating Scraped Surface Heat Exchanger

The patented HRS Unicus Series is a scraped surface heat exchanger specially designed and developed to offer a solution for those difficult heat transfer applications where very viscous fluids are used or fouling appears. The design is based on a traditional shell and tube heat exchanger with scraping elements inside each tube. The reciprocating movement of the scrapers mix the fluid whilst cleaning the heat exchange surface. This keeps heat transfer high and reduces downtime. In addition, the scraping movements introduce turbulence in the fluid increasing levels of heat transfer.

HRS - Model R Series - Rotating Scraped Surface Heat Exchanger

The HRS R Series is a scraped surface heat exchanger designed for the most difficult heat transfer applications, for example where very high viscosities and highly fouling fluids need heat treatment. Unlike the HRS Unicus Series, where the scraper movement is reciprocal, the HRS R Series technology uses a rotary scraper rod. This scraper rod can reach velocities up to 300 rpm resulting in very high levels of shear and mixing at the heat transfer surface; dramatically increasing the heat transfer rate.

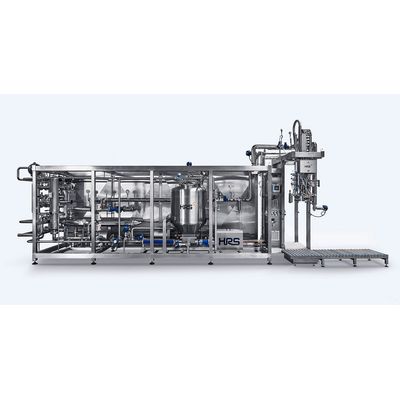

Systems - Food Processing Systems

HRS - Air Removal (Deaeration) System

Deaeration is principally intended to remove any air present in the material to be processed. The presence of air in many food products encourages oxidation and may be detrimental to product life or quality, in many cases it can increase thermal resistance and heating load. HRS has developed an air removal (deaeration) module which can be fitted into the production line before thermal treatment takes place.