Kalina - Klenski Ltd products

Grain Silos

Kalina - Flat Bottom Silos

Kallna-Klenski Ltd. manufactures metal silos for cereals such as wheat, corn, oats, rye, sunflower and others with volume of 20 to 5000 tons each. The silos are made of double galvanized steel components and then assembled on the bolt connection on reinforced concrete foundations with steel columns. In the foundation run channels for ventilation of the grain. At the top of the roof are placed vents for removal of hot air. The temperature of the grain mass is monitored by a thermal control system, which locate any areas with a high temperature due to higher humidity.

Kalina - Hopper Silos

Kalina-Klenski Ltd. manufactures silos from galvanized steel with conical bottom on metal legs. The bottom of the silos is inclined 45 ° and 60 °. In this type of silo emptying is carried by gravity means, without the need of facilities for forced removal of the grain.The metal legs of this type of silos step of striped concrete foundations or concrete slabs. These silos can be also used to deposit cells in feed mills. The company produces such silos with a capacity of 10 to 322 m 3.

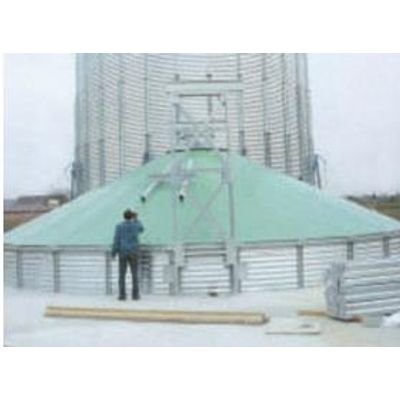

Kalina - Silos with Plastisol

Kalina-Klenski Ltd- manufactures silos for storing grain on the latest technical standards. We produce galvanized silos further processed with polymer coatings, such as plastisol. Plastisol binds strongly with galvanized steel and has practically a infinite life. This durable material can be performed only on the roofs of silos or the for the full body of the silo. As a positive indicator can be observed that the polymer coating reflects sunlight and reduces heat on the roof of the silo.

Kalina - Stainless Steel Silos

Kalina-Klenski Ltd- manufactures silos of stainless steel, which by their nature and functionality they do not differ from those of flat bottom silos. The difference is the materials, which is stainless steel instead of galvanized, and the silo is practically eternal- Such silos are used for storage of clean grain in organic farming and consumers who want to have eternal silos, without worry of any harmful effects of the atmosphere and environment.

Equipment

Kalina - Thermal Control System

The equipment is a digital system for thermal control and management of the ventilation of grain silos. The main function of the system is measuring the temperature of grain during its storage. The elements of this system are:

Kalina - Metal Foot Bridge

Metal footbridges are metal sites, which is placed technological equipment for loading the silos, but also and passage site for staff. Footbridges consist of a metal platform, guard rail with a height of 1.10 meters, columns and chairs. The metal columns and chairs are connected to the silo. Metal footbridges are made of galvanized steel or black steel (painted with primer and paint).

Kalina - Vibro Separator

The machine is designed for pre-cleaning of the entering grain in silo storages. The separator cleans the grain by sieving, where the powder and soft matter using the ascending air flow is separated from the grain flow. It is available in two versions according to productivity: 25 t / h and 50 t / h. In the first version the cleaning machine is with one section, one entrance and one exit and two vibro motors with power 0.55 kW. The second version is a machine with two sections within the body having two functional parts. Each part has a separate entrance, sieve and output for grain. Separately are collected rough impurities. Cleaned grain falls in aspiration section for separation of dust. This version is driven by two vibro motors with power 1.1 kW.

Grain Dryers

Kalina - Grain Dryers

Kalina-Klenski Ltd. offers dryers for drying and cooling grain with continuous action. Dryers can operate on gas or diesel and have different capacity for the different cereals. They can have from one to three fans for drying and cooling. For more information, see the technical specifications.

Mills

Kalina - Flour Mils Machine

MILLING MACHINES for production of flour and for animal feed processing plants . Construction of single-deck mills with room height of 6m. from 0.5 t/h up to 5 t/h processed grain. Construction of multi-deck mills to customer`s requirements. A highly efficient European technology is used in the grain milling. The most modern process for grain milling employs gradual separation of the external bran particles of the wheat grain and is known as Debranning in the world.