LAKTO Dairy Technologies products

Milking Systems

LAKTO - Electronic Pulsator

LAKTO PULS pulsator has a very simple design that can fit all brands. Provides perfect milking quality, does not get affected by vacuum level or environmental temperature. Due to indirect valve control by pilot valves, low powered coils (only 0,11 Amps.) are utilized. A cooling effect of the air intake on the coils is designed to prevent disorders of pulsation due to overheating, even on long runs.

LAKTO - Full Automatic Washing Unit

LAKTO CIP automatic washing unit controls the entire milking system via preprogramed electronic PCB. It controls the vacuum pumps, electronic pulsators and automatic cluster removers during the milking or washing processes and regulates the operations of these units and all connected functions. It automatically intakes the adequate amounts of cold, warm and hot waters required during the washing processes and the proper amounts of alkaline and/or acidic detergents required during the washing phases, respectively from thedetergent containers by dosing pumps. The unit automatically and respectively performs the rinsing,washing and drying operations.

LAKTO - Herringbone Quick Exit Milking System

The Quick Start Herringbone has been developed in the milking system to adapt the comfort of the animals in the entry and stop position to serial milking. After the milking, the exit time is accelerated with the hydraulic quick exit system. The stop bars are hot-dip galvanized and completely disassembled. Breast iron bars connected to the exit doors can be adjusted telescopically according to the size of the animal.

LAKTO - Herringbone Classic Milking System

In the herringbone milking system, stall anchors allow the animals to be milked to stand at a 30 ° angle at the milking site. There are double rows of zig-zag bars on each side, mounting posts and dirt holding plates at each milking point. It has a structure suitable for milking, flat at the exits and one door at the entrances. There is also a sliding entrance door lock and an exit lock with scissor mechanism. In this way, milking proceeds reliably and systematically.

LAKTO - Ovine Quick Exit Milking System

Quick exit stop bars are hot-dip coated and disassembled. The animal stops include rotary separators. Behind the animals, the stainless steel strainer and the water valve connected to the drainage channel clean the channel at each opening. The foundation of the building is embedded in the concrete, and the main carriers are connected to each other externally to strengthen the building. All mechanical and pneumatic components including air dryer are delivered with the system.

LAKTO - Ovine Output Milking System

There are butterfly doors between the stalls for easy settling of animals. Control can be performed from milking pits to facilitate milking control. Galvanized feeders are located in front of the stops on both sides of the pit. Feeders have individual locks. At the exits, the pneumatic cylinder opens the lock, locks and feeders are lifted with separate pistons and feed is poured into the feeder for the new coming animal.

LAKTO - Parallel Quick Exit Milking System

Parallel stop bars are hot dipped and demounted. In this way, the milker`s pit into the pit and take place comfortable. Sliding entrance doors, 4 or 5 animals fast exit doors and butterfly doors that can turn to the closed position without spring are available. The carcass, fittings and fittings are completely hot-dip galvanized steel. Animal stops include rotary separators. Behind the animals there is a stainless steel strainer plate. The water valve connected to the drain channel cleans the channel at every opening.

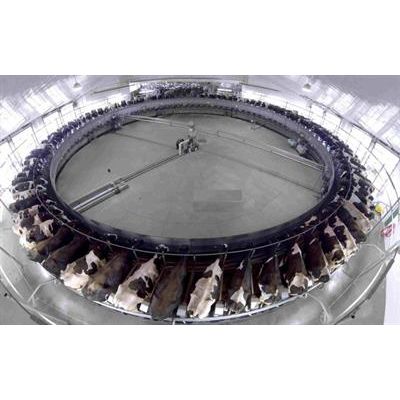

LAKTO - Rotary Milking System

In these milking parlors, which are focused on work efficiency, they put the milking heads at a single point, and the cows move on the rotating platform continuously and at constant speed and come to the front of the milker. The milker can only focus on milking more safely. It does not waste time walking between the heads, the speed of the platform can be adjusted according to the milking speed and milking time and yield of the cows. A uniform work routine creates a more relaxed environment. Milking procedures can be more consistent and efficient.

Barn Systems

LAKTO - Manure Scraper

It is possible to scrape two different manure alleys with the LAKTO -chained manure scraper set. It has two scrapers to clean the channels having a width of between 200 and 500cm. One set of manure scraper unit contains 2 scrapers in the determined dimensions, corner pulleys,driving unit with chain tightener, calibrated and hardened marine chain of length according to the barn requirements and a programmable electronic control box.

Milking Equipment

LAKTO - Milking Head

LAKTO-AK milking head is a new generation and original milking head with 4 years of intensive R & D activities. It is the first Turkish milking title that has received internationally patented and approved industrial design.