LogPro, LLC, DIVISION OF TIMBER AUTOMATION, LLC products

Crane Systems

LogPro - Lineal Log Crane

LogPro’s log handling crane technologies are custom engineered to each specific application. Forest Product Facilities that process in excess of 500,000 Green Tons of Roundwood per year should be operating at least one log crane system. Increasing fuel costs, manpower shortages, constant log run/yard maintenance cost and reduced fiber breakage provide an excellent return on investment for investing in a log crane. We design, manufacture, and service our log handling cranes from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience makes us the domestic leader in log handling technology.

Log Handling System

LogPro - Electric Pinball Kicker

LogPro’s log handling technologies are custom engineered to each specific application. We design, manufacture, and service our log handling equipment from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience makes us the domestic leader in log handling technology.

Material Handling System

LogPro - Debarker Feed Chute

LogPro`s log handling technologies are custom engineered to each specific application. We design, manufacture, and service our log handling equipment from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience makes us the domestic leader in log handling technology. LogPro`s log handling systems are optimizing woodyard operations throughout the forest products industry with XXHD design. Premium Efficiency electric drives & various log handling arrangements. This flexibility allows for reliable log handling while greatly reducing downtime in an easily maintainable & safe unit.

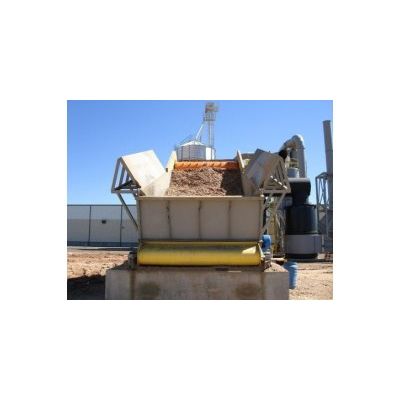

LogPro - Bark Hog Tower

LogPro designs and fabricates many components thatsupplement its main debarking line, among these are the major support systems such as the Bark hog tower. These structures are custom-designed to fit the customers` specific production requirements. They are versatile to allow for large and small hogs, and various chute-work and conveyors need ed to tra nsport the bark.

LogPro - Reclaim Conveyor

LogPro’s log/chip handling technologies are custom engineered to each specific application. We design, manufacture, and service our log handling equipment from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience makes us the domestic leader in log handling technology. LogPro’s log handling systems are optimizing woodyard operations throughout the forest products industry with XXHD design, Premium Efficiency electric drives & various log/chip handling arrangements. This flexibility allows for reliable chip handling while greatly reducing downtime in an easily maintainable & safe unit.

LogPro - Radial Chip or Bark Stacker Systems

LogPro designs, fabricates and supplies custom designed radial stackers or bark stackers that can be fixed or traveling. Each stacker is designed with the “complete system” philosophy, which takes into account material bulk density, topography, feed rate, accessibility, as well as many other factors. A flexible spout can be attached to minimize free falling material to eliminate fiber leakage. The Traveling Stacker can be mounted on rails or can be a rubber tire type design.

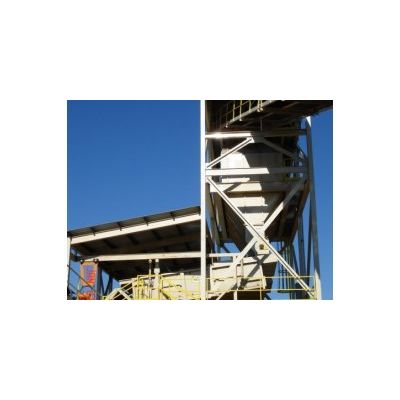

LogPro - Chip Screen Tower

LogPro designs and fabricates many components that supplement its main debarking line, among these are the major support systems such as the screen tower. These structures are custom-designed to fit the customers’ specific production requirements. They are versatile to allow for high-volume screens, re-chippers, cyclones and various chute-work and conveyors needed to transport the chips.

Lumber Equipment - Baxley - Transverse Edger Pieces

Hi-Speed Optimized Traverse Edger System

The 2 Saw Edger for Centerline Feed is designed to enhance efficiency and precision in milling operations. This equipment features a chain race for the RC80-2 summit top chain, extending through the outfeed for strip drop-out. Three overhead press rolls on the outfeed chain ensure stable and consistent material handling. The independent arbor saw modules slide on 3-inch chromed shafts, driven by two 75 HP, 1800 RPM motors with V-belt drive to the arbor shafts, enhancing the cutting performance. The edger includes 2 7/16-inch diameter TG&P arbors with 15-inch collars, coupled with two linear positioning saw set cylinders with proportional valves for exact adjustments. Drive guards are installed for safety, and additional press rolls are strategically placed within the edger frame to ensure smooth feed and discharge of materials. However, the saws themselves are not included. The unit also features a six-knife head for 12-inch coverage driven by a 200 HP motor with V-belts and sheaves, controlled by a linear positioning top head set cylinder assembly. The operation is powered by a 30 HP VFAC drive, ensuring consistent and powerful throughput. This edger is a robust addition to any milling operation, promising durability and precision in lumber production.