Mulmix S.p.a. products

Cereal Storage

Mulmix - Flat Bottom Grain Silos

The flat bottom grain silos (FP series) is used for the storage of granular cereals with maximum apparent density of 0.85 t/m3. It is installed on a concrete base in which ventilation channels can be obtained. In the storage flat bottom grain bins loading is performed through the central dome both by means of pipes and conveyor devices positioned on dedicated gangways. Silo unloading is done by means of mechanical conveyor devices positioned both in the subterranean tunnels or in the channels obtained in the base. In silos of greater size and height, side unloading channels can be fitted (usually installed on the 10th ring) for partial silo unloading without the need for mechanical devices.

Mulmix - Metal Hopper Silos

The 45°and 60° metal hopper silos model CI are used in mills, in feed mills and in storage plants where the complete emptying of silos is necessary but it should be performed without the aid of mechanical conveyors or operators. They can be even used to store products with difficult flowing since the hopper facilitates it. The discharge cone is made of Z600 galvanized sheet. CI silos are available in many versions, from 120 to 2400 m2. By the way other sizes can be easily required. The silo is designed in compliance with EUROCODE EN-1991-4 standards.

Mulmix - Quick Loadings Silos

The quick loading silos (CR series) are used for loading means of transport such as trucks and trains. The cereal is loaded in the silos at the rate provided by the conveyor devices in the plant and unloaded by means of gravity through an automatic or manual shutter positioned at approximately 4.2 meters off the ground. The use of a quick loading CR silo speeds up vehicle loading, making the cereal always available for delivery including without the use of mechanical devices.

Mulmix - Grain Dryers

The DRY-MX grain series dryers are used for the drying of cereals and oilseeds in order to improve their storage and conservation quality.

The product is loaded in the upper part of the dryer, descends by means of gravity through the drying column and loses humidity until reaching the desired parameters. The particular geometry of the ducts in which the product flows and the pulse outlet guarantee a homogeneous flow and a continuous product mixing.

Industrial Maxima HD

Mulmix - Unloading Shutters

They are special shutters for te compact pneumatic or motorized unloading of products from redlers. They are equipped with manual or automatic brush for the correct removal or residual products sticking on the chain.

Zoomill Feed Mills

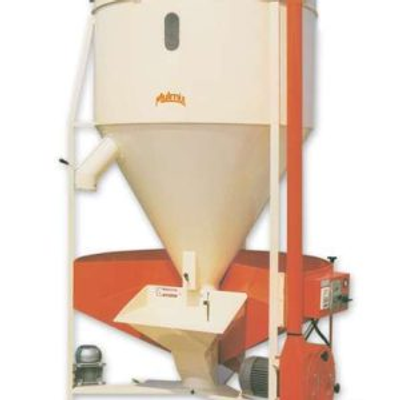

Mulmix - Mill and Mixer

This is the simplest and cheapest solution for customers who wish to produce their own animal meals. The DUPLEX includes both milling (orange colour) and mixing functions (ivory colour) in one single machine; all functions are controlled by an electrical panel installed on board the machine. The grinding part consists of a cereal hopper with capacity of 750 kg, a magnet for elimination of any ferrous wastes and a mill with 36 hammers. With 360° screens and incorporated fan for cereal suction and pneumatic conveying of flour. The mixing part includes a 1000 kg mixer with vertical screw, an hopper for ingredient addition and a filter unit for connecting of dusts from the pneumatic conveying.

Mulmix - Feed Production Unit

UP4 is the ideal solution for farms and industries who wish to produce directly feed for their livestock (cattle, poultry, pigs, sheeps, etc) in a compact-sized plant at a price that is easy to recover. The dozens of units produced so far are proving that UP4 fully satisfies those requirements. The drawing illustrates an UP4 with its basic configuration. According to different customer requirements, the equipment can be completed with a series of auxiliary systems: cereal storage, additive loading unit, liquid spraying lines, pellet milling plants, bulk look out for feeds.

Mulmix - Feed Production Unit

Using tested mechanical components of the UP4 production unit, we have developed a new compact unit suitable for feed production up to 8 T/h. It is the ideal solution for customers who wish to produce large quantities of feed, with recoverable costs. According to different customer requirements, the UP8 production unit can be completed with a series of extra systems such as: cereal storage, additives loading unit, liquid spray lines, pellet mill plant, finished product bins etc.

Mulmix - Silos for Animal Feed

The SM silos for animal feeds are used for the storage of small quantities of feeds, meals and granular cereals with maximum apparent density of 0.651 t/m³. A standard corrugated steel silos to which an unloading hopper is fitted, is assembled on a support structure consisting of uprights and wind-braces. The self-supporting roof consists of hot-galvanised steel-plate trapezoidal elements fixed on the cylinder; the standard version is supplied with breather on the roof and spring opening system with manual ground control. The cylinder is made of corrugated S350GD (UNI EN10346) steel sheets with Z450 galvanised covering (equivalent to 450g/m2 of zinc) which ensures long lasting protection against atmospheric agents.