- Home

- Companies

- Ocrim S.p.A.

- Products

Ocrim S.p.A. products

Wheat

Ocrim - Milling Process for Ground Wheat

The milling process depends on the type of ground wheat and, together with the fitting of the various machines, establish the final outcome:

Ocrim - Wheat Cleaning and Conditioning System for Milling

The pre-cleaning stage is the first stage of cereal processing before ensiling. The subsequent first and second cleaning stages relate to the treatments that wheat undergoes before milling. These operations have the aim to remove impurity and foreign bodies from wheat, including the conditioning process, in order to obtain the best possible result in terms of yield in the grinding stage.

Other Products

Ocrim - Grain Processing Plant for Starch Production

Ocrim supplies complete plants, upgrades and expansions for processing the various grains, as well as for the production of flour suitable to obtain the starch used for various purposes. Even in this sector, Ocrim has significant experience stemming from the great professionalism of technologists and plant engineers, based on the type of flour processing that takes place in the subsequent starch production stage, in order to provide the correct product, with the right features, for the starch production line.

Ocrim - Feed Mills

Ocrim provides solutions which permit to produce sheep, fish, cattle and poultry feeds at optimal costs thanks to plants high level production, limited energy consumption, minimum maintenance and restrained capital expenditure. Ocrim offers both technical-engineering services and services to improve recipes.

Ocrim - Flour Blending Solutions for Milling Plants

These days flour blending plays a fundamental role in the daily milling plants efficiency and it represents its real added value. This is due to the fact that it allows the production of specific and “ready to use” products, which can be customized according to every single market or client.

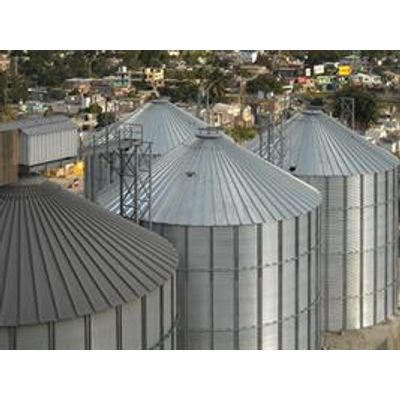

Ocrim - Cereals Storage Bin

Ocrim designs, builds and supplies blending bins, grain tempering bins and finished product storage bins (flours, bran, by-products etc.). Ocrim team realizes, according to the milling plants’ needs, square or circular bins, stainless steel or painted steel bins, corrugated plate or smooth sheet bins. Ocrim great experience in the construction and design of milling plants has been very important for the strengthening of its specific business areas. This specialized approach is the reason why the design and the building of storage bins are fundamental operations for the company core business.

Ocrim - Complete Maize Milling Plant

Maize has been referred to as "the cereal of the future" due to its high nutritional value and the wide utilization of its products and by-products. Ocrim has given great importance to maize milling plants since 1945. In fact, a group of technologists is entrusted with the task of conducting this sector specific research. Thanks to studies completed, today Ocrim maize milling plants work all over the world in order to supply the most sophisticated products through dry, semi-humid and mixed degermination. Ocrim offers complete milling plants, plants revamping and upgrading for the processing of various types of maize used for the production of semolina, grits for beer, hominy grits for corn flakes, pre-cooked meal and other products obtained through the different type of degermination.

Ocrim Products

Ocrim - Single Channel Square Plansifter

Due to reduced dimensions, high output and rapid change of technological schemes, this machine is recommended for sifting, calibrating and checking milling products. It can be supplied in 2 configurations: leaning or suspended. There is also a version with sieves coated internally and externally in stainless steel.

Ocrim - Vertical Steam Oven

Ideal machine for the heat treatment of cereal for flocking. For the heat treatment of cereal for flaking. Vertical oven with tapered modular elements to ensure even product flow. The oven body is composed as follows: between the inner and outer walls, both of which are made of stainless steel, there is a layer of insulating material that ensures low heat loss and thus high efficiency and quickly reaching steady-state conditions. Inspection indicator lights and openable doors are arranged along the body. All parts in contact with the product are made of stainless steel. The heat treatment of the cereal takes place via steam delivered internally from distribution ducts designed to ensure maximum efficiency and uniformity. Thermometer, pressure gauge and valves ensure control of the adjustment parameters.

Ocrim - Stainless Steel Conical Degerminator

Machine for the degermination and peeling of maize. It guarantees the highest quality with a semi-wet system, in the production of perfectly peeled large slices like hominy grits for the production of corn flakes, corn rice and precooked flours.