Ozbil Agricultural Machinery products

Potato Planter

Ozbil - Two Rows Automatic Potato Planter Machine

The machine is connected to a tractor through a three – point hitch mechanism. Seeds prepared in advance for plantation are filled into the storage. The potato tubers inside the storage are automatically taken by conveyor chain with two rows of metal hollow pots on. The conveyor chain carries the seeds upper part. While carrying process, if the seeds are too much on the hollow pots, they are dropped back from the pots to the storage. The seeds on the pots are dropped to the beds opened by planter tine. When the model with seed dressing system is preferred, while the planting process, seed are dressed at the same time. Plantation is completed by covering the dropped seeds with the help of furrow closing moldboard tines.

Potato Harvesters

Ozbil - Two Rows Potato Harvester Machine

The machine is connected to a tractor through a three-point hitch mechanism. The driveshaft is connected to the power take-off a tractor. Diving distance of the front cutter discs and depth of the carriage setting wheel are adjusted according to soil conditions. Planted furrows are cut by cutter discs and taken inside the machine by the receiving blade (shovel). Received soil is separated from the potatoes by making long pallet moving and jumping movements. Potatoes purged of soil are left on the soil surface behind the machine in a neat way.

Ozbil - Two Rows Potato Harvester Machine

The machine is connected to a tractor through a three-point hitch mechanism. The driveshaft is connected to the power take-off a tractor. Diving distance of the front cutter discs and depth of the carriage setting wheel are adjusted according to soil conditions. Planted furrows are cut by cutter discs and taken inside the machine by the receiving blade (shovel). The soil received is scattered by the front scattering shaker mechanism and conveyed to the pallet unit. Continuing to be sifted on the rolling pallet, the soil is poured into the sifting unit after a certain height. The sifting unit uses oscillations and shaking movements to separate the soil from potatoes and drop it under the sift. Potatoes purged of soil are left on the soil surface behind the machine in a neat way.

Ozbil - Two Rows Potato Harvester Machine

The machine is connected to a tractor through a three-point hitch mechanism. The driveshaft is connected to the power take-off a tractor. Diving distance of the front cutter discs and depth of the carriage setting wheel are adjusted according to soil conditions. Planted furrows are cut by cutter discs and taken inside the machine by the receiving blade (shovel). The soil received is scattered by the front scattering shaker mechanism and conveyed to the pallet unit. Continuing to be sifted on the rolling pallet, the soil is poured into the sifting unit after a certain height. The sifting unit uses oscillations and shaking movements to separate the soil from potatoes and drop it under the sift. Potatoes purged of soil are left on the soil surface behind the machine in a neat way.

Potato Grass Shredder

Ozbil - Three Rows Potato Grass Shredder

The machine is connected to the tractor with a three-point hitch system. The cardan shaft (shaft) is connected to the tractor PTO shaft. The tractor and the potato shredder, which is connected to the tractor with a 3-point hitch system, is positioned so that the wheels of the tractor enter the potato furrows, and the ground height of the mulcher is adjusted both with the tractor hydraulic arms and the roller or wheel height adjustment behind the machine. At the first start, the PTO shaft of the tractor is moved slowly. For this, the operator must slowly lift his foot off the tractor clutch. Otherwise, the shaft may break. When the blades of the machine reach a sufficient rotation speed, the tractor moves through the furrows and the potato grass is shreddered and distributed homogeneously on the field surface.

Hoeing Machine

Ozbil - Three Rows Fertilizing Hoeing Machine

The machine is connected to a tractor through a three-point hitch mechanism. The fertilizer storage is filled and the driveshaft is connected to the power take-off of a tractor. The amount of fertilizer to be dispensed is adjusted with the help of a handle. Hoes of the machine enable hoeing gaps between rows of planted crops and thus ruffles soil. Concurrently, the fertilizer inside the storage is dispensed on to the ruffled parts through the hoses on the backside of hoes. The fertilizer is dispensed in an equal and balanced way so as not to touch the crop with the help of furrow-closing moldboard tines. Thus hoeing, fertilization and ridging operations are completed without disturbing the furrow order.

Ozbil - Three Rows Non Fertilizing Hoeing Machine

The machine is connected to a tractor through a three-point hitch mechanism. Hoes of the machine enable hoeing gaps between rows of planted crops and thus ruffles the soil. The ruffled soil is filled next to crops with the help of furrow-closing moldboard tines. Thus hoeing and ridging operations are completed without disturbing the furrow order.

Rotovator

Ozbil - Rotovator

The machine is connected to a tractor through a three-point hitch mechanism. The driveshaft is connected to the power take-off a tractor. Motion is taken from the power takeoff as 540 RPM and transmitted to the rotor with blades with the help of gearboxes. Soil processing is started after the operation depth is adjusted as desired with the help of the sledge supports on the two sides of the machine. Low progression speed creates smaller soil pieces, high progression speed result bigger soil pieces. The disintegration which is most suitable to the soil structure can be enabled by adjusting the movement speed of the tractor.

Pneumatic Precise Seeder

Ozbil - Two Rows Pneumatic Precise Seeder

The machine is connected to a tractor through a three-point hitch mechanism. The seed storage is filled and the driveshaft is connected to the power take-off a tractor. The seeds cling to the holes on the planter chromium plate one by one by vacuum. The seeds carried with the rotation of the planter plate are dropped on the sowing bed opened by the front planter tines with the elimination of the vacuum effect. Plantation is completed by covering the dropped seeds with the help of furrow closing moldboard tines.

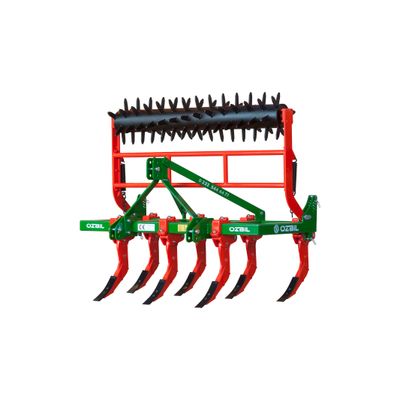

Chisel Plough

Ozbil - Normal Type Chisel Plough

The machine is connected to a tractor through a three-point hitch mechanism. If a rolling harrow combination (roller) is wanted to use, it is removed from its pin and adjusted. Number of tines can be reduced and the distance between tines can be changed depending on the structure of soil, humidity and operation depth. Soil processing is started after adjusting the desire to depth from the tractor`s hydraulics.