Redono Oy products

Urban Crop Solutions

Redono - Model FarmFlex - 40" Freight Container

A flexible and climate controlled 40′ freight container with a state-of-the-art leafy green growing rack setup. This system gives you a fully automated 4-layer growing solution.

Redono - Model FarmPro - 40 Ft Fully Automated Freight Container

The FarmPro is a 40 ft fully automated freight container with a state-of-the-art leafy green growing system. This system gives you a fully automated 4-layer growing solution. Commonly used as: Any cost-driven production process.

Varicon Aqua Photobioreactors

Phyco-Flow - Model 600L - Serpentine Photobioreactor

The Phyco-Flow is an innovative new serpentine design that scales easily to meet increased production requirements. This photobioreactor dramatically reduces labour and handling problems with a patented self-cleaning mechanism. The light collecting tubes are made from Duran grade borosilicate, in partnership with SCHOTT AG Glass. This results in a highly productive system with a superior lifespan to many competitors. Complete and integrated process control can be undertaken with a VAS AlgaeConnect control unit.

Redono - Model Phyco-Pyxis 1-4 m³ - Fully Controlled and Automated Enclosed Photobioreactor

The Phyco-Pyxis brings a fully controlled and automated enclosed photobioreactor concept to the marketplace. The system is available in a range of incremental sizes from 1m3 to 4m3. The reactor is internally illuminated with LED or Gro-Lux lighting that can be tailored to specific photosynthetic requirements; and is mixed by aeration, which significantly reduces mechanical shear. Standard fabrication is in glass reinforced plastic, with a top overflow for harvesting and a bottom outlet for draining, the top of the reactor is removable for maintenance and cleaning purposes.

Redono - Model Phyco-Lift 5 – 600L - Airlift Photobioreactor

The Phyco-Lift range of photobioreactors provides a robust lab or pilot plant sized solution to growing algae for commercial or research purposes. The simple modular design allows for scale-up with negligible performance drop; and the reactor can be operated in either airlift or column mixing configurations, both of which allow for low shear, high turbulence and high mass transfer culturing conditions. The reactor can be equipment with the VAS AlgaeConnect control unit, and a range of sensor or lighting options to improve cultivation conditions.

Other Products

Redono - Model HydroHumala PILOT - Indoor Hydroponic Unit

UrbanHopsFarm is an indoor hydroponic hops farm solution for year round production of fresh hops for breweries. Our HydroHumala PILOT will demonstrate the proof-of-concept by producing fresh hops in collaboration with Tornion Panimo’s brewery and Metropolia University of Applied Science, Urbanfarmlab, located in Vantaa.

Redono - Bio Feed Unit

Industrial sidestreams can be pretreated in the BioFeed unit to produce organic liquid fertilizers (BioFeed). The purpose of the BioFeed unit is to remove the containing solids and eliminate any unwanted bacteria or other organisms and impurities from the industrial sidestreams. The processed waters are produced into an excellent BioFeed-fertilizer for the BioAlgae and BioPlant units. BioFeed-fertilizers are considered as quality fertilizers for microalgae and plant cultivation, containing the necessary nitrogen and phosphorus, incl. other macro- and micronutrients. During the pretreatment process, the industrial sidestreams are being monitored and controlled to guarantee a continues nutrient recycling process in the REDONO process.

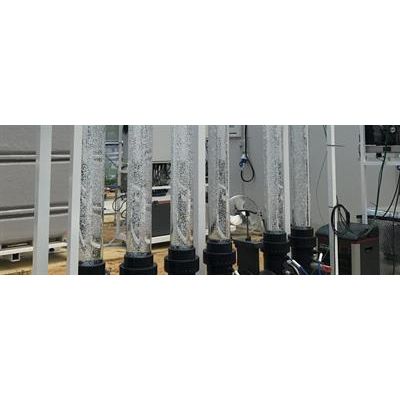

Redono - Bio Algae Unit

The BioAlgae unit is designed to eventually purify the recycled waters, while cultivating microalgae in the tubular photobioreactors (PBR), combined with high-tech LED-growlights. The unit can grow microalgae species like Haematococcus Pluvialis and Auxenochlorella protothecoides. Please read below more details of our microalgae species. The purified waters can be returned to nature or used as industrial process water.

Redono - Resting Continuous Rotifers System

This is the easy way to keep an emergency supply of rotifers to hatch when needed. Grown by Florida Aqua Farms these are the dormant cysts of rotifers. They last virtually indefinitely in a freezer and can be hatched easily when needed. Hatch by covering with sterile seawater (10 to 15 ppt) in a shallow tray at 20-25 deg C under constant light. Hatching begins after 24 hours. Feed with a small amount of green-water from either concentrated algae (e.g. nannochloropsis) or live algae. After 2 days transfer to a larger container filled with sterile seawater (10 to 15 ppt and feed again. After 4 days transfer to a tank container filled with more clean sterile half strength seawater and more green-water and light aeration. Within 20 days each 100 rotifers will have become 1 billion rotifers. You can start harvesting from 7 to 10 days after hatching.