TEWE Elektronic GmbH products

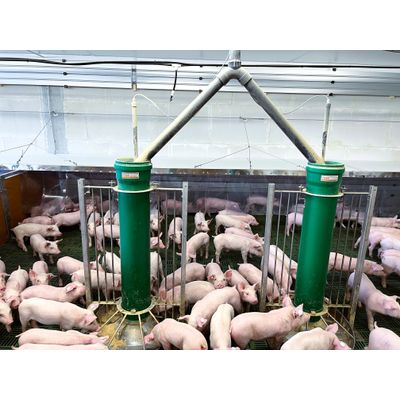

Pneumatic Feeding

TEWE Elektronic - Group Pneumatic Feeding

Enough feed for animals of every size: Whether big or small, strong or weak, every animal receives adequate feed here, because the many benefits of the Airfeed pneumatic feeding solution reveal themselves in group feeding. Airfeed automatically mixes and doses small and large batches according to the size and composition of the group, and dispenses them to the animals in several portions. Block feeding in several small or large portions allows even small animals, who would otherwise be hassled by the stronger animals, to eat undisturbed. This ensures every animal is well fed and the groups can be assembled and fed according to their age and size. For example, sick, underweight or weak animals can be grouped together. The size of the group can also be adjusted as desired.

TEWE Elektronic - Sow Pneumatic Feeding

Each individual sow can receive the exact feed they need, whether that be in the waiting pen, breeding centre or farrowing pen. The feed is transported in dry form and can then be dispensed at the trough either in dry or liquid form. This allows the benefits of pneumatic feeding to be combined with those of liquid feeding. Optionally, one outlet pipe can be provided for every 4 sows kept in the crate. Group housing at the cross trough can also be implemented. The feed can individually adjusted to the needs of each individual sow according to their age, weight and litter size. The TEWE mixing and dosing technology prepares portions of all sizes with no downtimes and mixes in minute quantities of additives as required. Airfeed is controlled via the central feeding computer which monitors all functions and processes.

Dry Feeding

TEWE Elektronic - Group Feeding - Dry

Around the world, pigs are most commonly kept in group housing. For decades now, TEWE has been meeting the nutritional requirements of pigs in groups with well-developed, precise and proven technology which operators can fully rely on. TEWE dry feeding technology stands the test of time, and it’s easy to install and maintain. Depending on the equipment, TEWE’s dry feeding can be used to achieve very high dosing accuracy, maximum feed hygiene, customised programming of feeding curves, and much more. Optionally, the animals can be fed up to the biologically feasible optimum via sensors installed in the automatic feeders, without running the risk of overfeeding the animals, wasting feed or causing feeders to overflow.

Liquid Feeding

TEWE Elektronic - No-Residue Liquid Feeding

A functioning no-residue liquid feeding system guarantees optimal hygiene and well-fed, healthy animals developing in line with their planned weight gain. Not only does this require complete feed uptake, but there also can’t be any residues or waste left in the pipes or the feeding system. In order to ensure both of these things, a wealth of practical experience and no shortage of innovative technology have gone into the TEWE feeding computers and the development of the system for no-residue liquid feeding. Our no-residue feeding optimises feed consumption while managing it to ensure that every animal always receives the nutrition it needs.

TEWE Elektronic - Liquid Sensor Feeding

Sensor-controlled liquid feeding is used on many farms, especially for fattening pigs. Here, the animals practically control their own feed allocation according to their own needs using the feeding computer’s control electronics. The animals are provided with liquid feed ad libitum by means of a sensor which detects the fill level of the trough and/or the time left until the trough will be empty. When the sensor detects that the trough is empty, the animals receive fresh feed either immediately or at the nect feeding time. TEWE’s self-developed control technology brings together all essential data in the feeding system and controls everything independently in line with the specifications.

Insect Feeding

TEWE Elektronic - Insect Liquid Feeding

Even when fulfilling complex requirements and meticulously documenting processes, the liquid feeding technology for insects remains just as easy to use. It can be adapted to small and large insect farms in both manual and fully automatic form. The stringent hygiene standards of insect fattening are met by thorough cleaning and rinsing programs. Agitator and pump programs thoroughly mix feed batches, so the insects receive fully homogeneous nutrient compositions at all times. The size and performance of the system is customised to the respective feed cycle.

TEWE Elektronic - Insect Dry Feeding

Some insects require a high proportion of dry matter in their feed. The dry feeding systems developed by TEWE are technically innovative with a high degree of automation, which makes work easier and enables precise feeding.

On-Demand Feeding

TEWE Elektronic - Single-Animal Feeding

In on-demand feeding, the animals activate sensors that trigger mechanisms through which individual data about the animal – such as the previous feed quantity, weight and health status – can be viewed. The feed quantity is adjusted to the animal’s age, weight class and health status, and supplemented with additives if necessary. The goal of on-demand feeding is to feed the animal automatically in accordance with its nutrient, mineral and vitamin requirements. The feeding technology used for this is decisive. On-demand feeding can be implemented in farms of all sizes and tailored to the group size. This also allows on-demand feeding systems to be integrated into new or existing barn concepts.

TEWE Elektronic - Sorting Gate - On Demand

At the sorting gates, all of the pigs are measured individually and can then be split up and assigned to two or more feeding groups according to the defined criteria. An integrated weighing system developed by TEWE subsidiary TELL can be added to the sorting gate. According to their individual weight, the animals are recorded, automatically sorted via the gate, and then fed individually in the eating area. This allows the animals to be fattened at the same rate, avoiding large weight differences within the group.

Animal Welfare

TEWE Elektronic - Animal Welfare - Roughage

Due to socio-political changes, calls for greater animal welfare in agriculture have been increasing significantly for years. EU regulations and standards not only mandate action to continue improving animal welfare, but also the documentation of this action. Feeding animals is undoubtedly one of the most important factors for their wellbeing. It’s scientifically proven that providing roughage not only greatly reduces cannibalism between the animals, but also reduces stress and improves feed uptake. To make life as easy as possible for farmers, the TEWE team has developed fully automated solutions for providing animals with roughage and manipulable materials, such as straw, structural pellets, maize silage, etc. Whether pneumatically or by chain, manually or automatically via the feeding computer, there are a variety of suitable solutions for an optimal and reliable supply of roughage to efficiently increase animal welfare.