- Home

- Companies

- Vikotech Makina

- Products

Vikotech Makina products

Granule Extrusion Systems

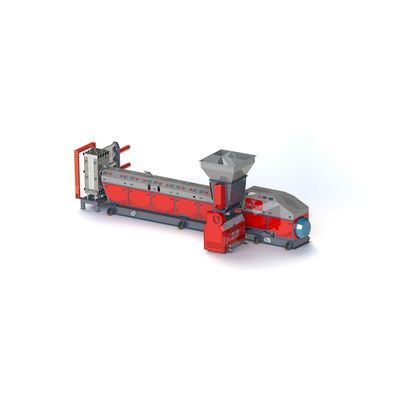

Granule Extruder (Top Feed)

Top Feeding Granule Extruders are machines that pelletize plastics for free flow, especially in the form of burrs. Crushed, washed and clean plastics or dried plastics can be processed. The plastics to be granulated flow from the top feeding chamber in free flow to the extruder screw. An engine driven vertical feed screw is inserted into the top feeding chamber to feed plastics (such as thin-walled burrs) that may have free flow problems. Screw diameter, aspect ratio (L/D), number of degassing zones, filter model and filter diameter are designed according to the condition and shape of the material to be processed. The screw is provided with a special bimetal welding, which provides additional protection against the abrasive effects of plastics. Screw and barrel are hardened by nitriding and induction process.

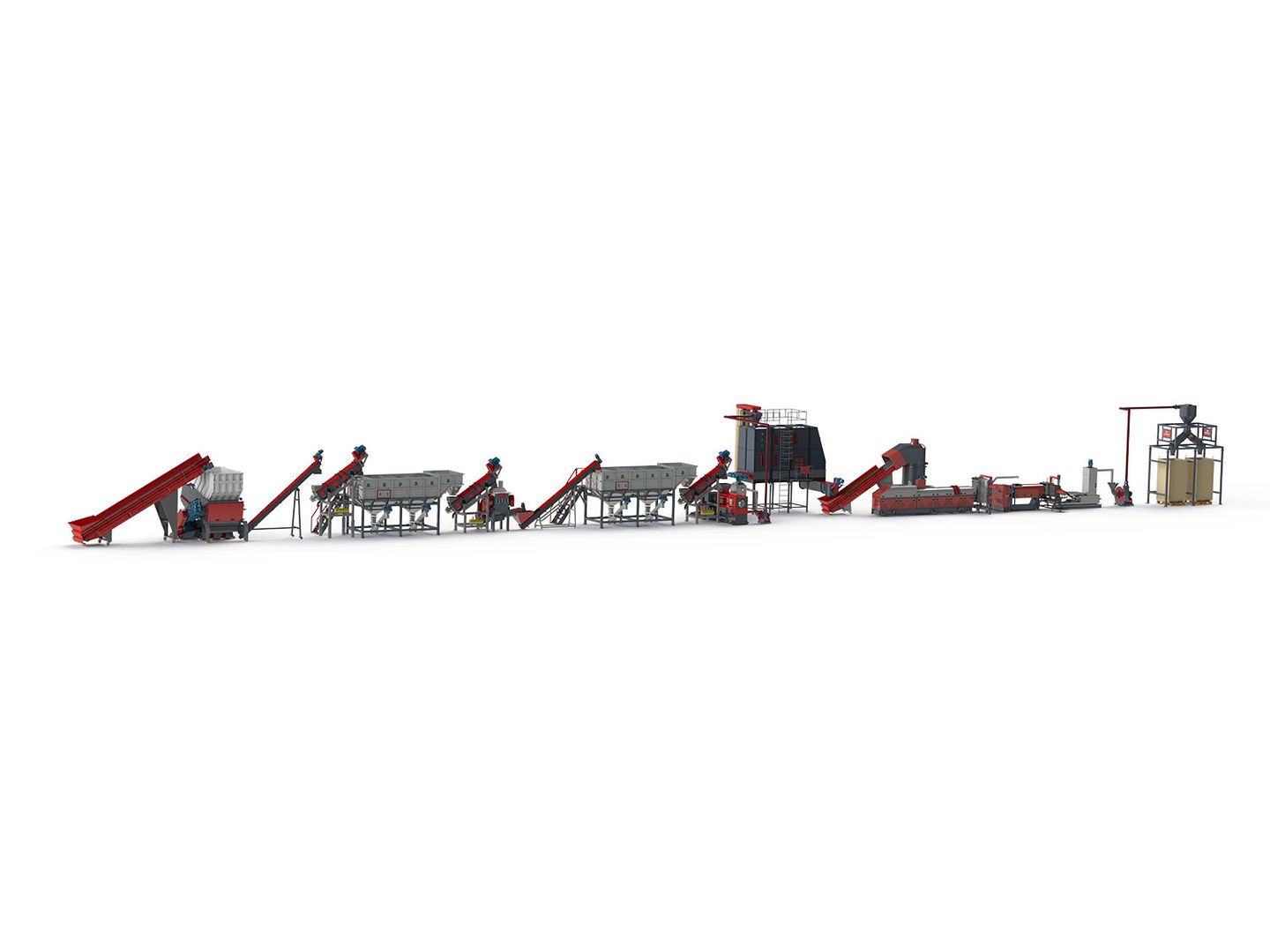

Granule Extruder (Side Feed)

There is a lots of waste plastic in environment such as LDPE, HDPE, LLDPE, PP, OPP, BOPP, CPP, PS, EPS, ABS, after all this plastic waste collected, they will be taken to recycling plants. They will be separated. All the cleaned and dried materials will go to Extruder machine, where becomes a reusable granule. Two-stage extruder machine is working as a machine coupled with the continuation of current extruder. The biggest reason for the preference of this machine during heavy printed plastic production or in cases where it is difficult to release the harmful gases out of the melted plastics, then it is the best granule solution.