- Home

- Companies

- Vikotech Makina

- Products

- Granule Extruder (Top Feed)

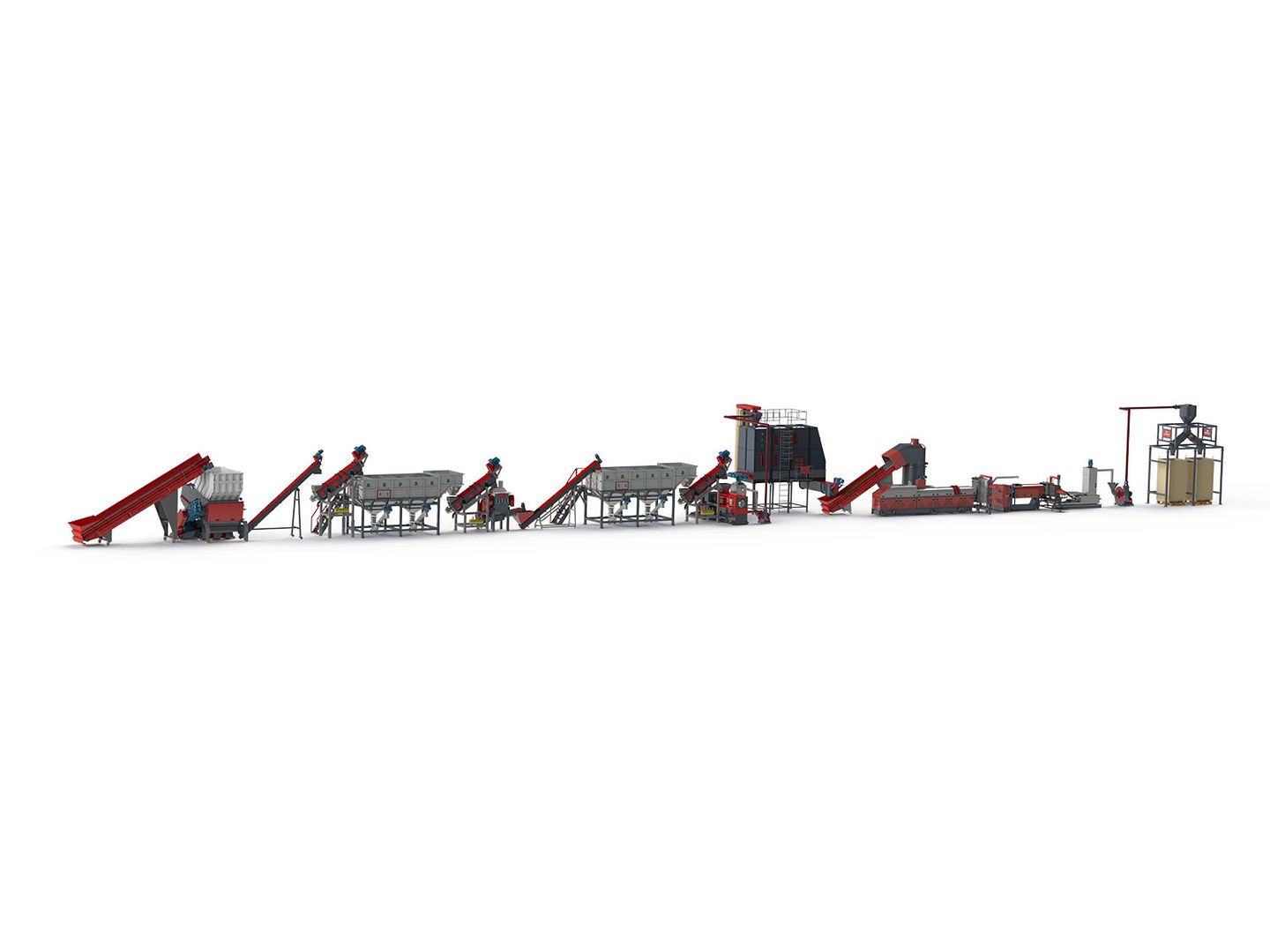

Granule Extruder (Top Feed)

Top Feeding Granule Extruders are machines that pelletize plastics for free flow, especially in the form of burrs. Crushed, washed and clean plastics or dried plastics can be processed. The plastics to be granulated flow from the top feeding chamber in free flow to the extruder screw. An engine driven vertical feed screw is inserted into the top feeding chamber to feed plastics (such as thin-walled burrs) that may have free flow problems. Screw diameter, aspect ratio (L/D), number of degassing zones, filter model and filter diameter are designed according to the condition and shape of the material to be processed. The screw is provided with a special bimetal welding, which provides additional protection against the abrasive effects of plastics. Screw and barrel are hardened by nitriding and induction process.

The engine under the inverter controlled (speed controlled) screw speed, plastics with different fluidity can be granulated with the same pressure and efficiency. This ensures efficiency and high quality.

High energy savings are achieved by the direct coupling connection used between the engine and the gearbox, the ceramic heaters, the insulated heaters covers with fan and the inverters, high energy savings are achieved.