Zanin s.r.l.

- Home

- Companies

- Zanin s.r.l.

- Products

Refine by

Families

10 products found

Zanin s.r.l. products

Cleaners and Separators - Sieve Cleaners

Zanin - Sieve Cleaner

The PSC5 Cleaner is an industrial cleaning machine designed to effectively separate fine, medium, and large impurities from grains and other uncleaned products. It employs a double-step cleaning system that enhances its ability to process materials. The operation begins with the gravitational entry of the uncleaned product, distributed evenly through a counterweight system. An air flow initially removes lighter impurities before the product reaches the sieve compartments. The upper sieve targets larger impurities, whereas the lower sieve focuses on finer impurities. This machinery concludes the cleaning by employing decelerators and additional air flows that segregate remaining lightweight impurities for disposal via cyclone or filter systems. Suitable for wheat with specific weight and moisture conditions, it offers varying capacities for pre-cleaning, cleaning, and calibration, emphasizing efficiency in larger-scale operations.Cleaners and Separators - Drum Cleaners

Zanin Fratelli - Rotary Pre-cleaner for Grain

The PPR Rotary Pre-cleaner is designed to efficiently eliminate both fine and large impurities from grain, safeguarding the quality of the produce before it is introduced to the drying process. By homogenizing the grain, it prevents lodgements and optimizes power usage. The aspiration variant of the machinery helps in minimizing dust emission into the environment, ensuring a cleaner operational setting. With a cylindrical rotary drum featuring interchangeable perforated screens, it allows the clean grain to pass, while larger impurities are removed at the drum's exit. The screen choices are adjustable based on the grain size, moisture content, and waste type. The system is versatile, able to manage cleaning capacities ranging from 20 to 375 tons per hour, making it adaptable for diverse operational needs.Cleaners and Separators - Air Cleaners

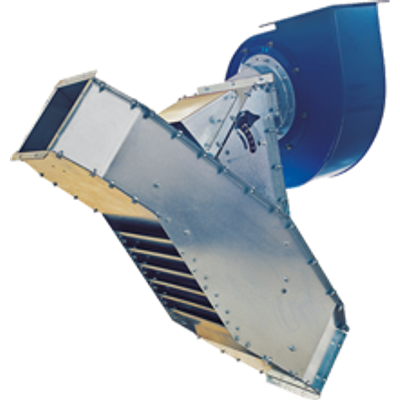

Zanin - Inclined Aspiration Cleaner for Grain Processing

The PA-I Inclined Aspiration Cleaner is a versatile and essential solution for the grain industry. It is designed to efficiently remove fine dust particles from grain during processing, making it a crucial component in maintaining grain quality. Its applications are diverse, allowing installation at virtually any point within a processing system, including elevator and silo inlets. The operating principle involves gravity-fed distribution of the product across its width, followed by a transverse airflow that removes lighter particulates, which are subsequently separated using cyclones or filters. The airflow can be precisely adjusted via the 'false air' mechanism. The cleaner is available in various sizes and models, with cleaning capacities ranging from 30 to 120 tons per hour, calculated using wheat with specific parameters. This range offers flexibility to suit different processing needs, ensuring effective grain cleaning across multiple industrial applications.Cleaners and Separators - Treatment

Zanin - Single Step Hulling System

The Single Step Hulling System is engineered for the efficient hulling of various grains, leveraging a combination of gravity feed and centrifugal forces to achieve precise shelling. Incoming grains are channeled into the huller through a feed auger and undergo centrifugal hulling. A pivotal feature of the system is the use of a perforated basket, which can be adapted based on the specific product being processed. The design includes an advanced aspiration system that distinguishes between the lighter glumes and the denser grains, directing them to an oscillating plate separator. This element efficiently segregates clean product from impurities, with the latter being expelled and rerouted back to the feed auger. The machinery is versatile, available in multiple models, with capacities ranging from 400 to 900 tons per hour, specified for spelt wheat with a relative humidity of 14% and a clean product weight of 0.60 tons per cubic meter.Cleaners and Separators - Seeds Selection

Zanin - Destoner for Cereals

The destoner for cereals is an essential equipment utilized for the separation of heavy impurities such as stones, metals, and other unwanted materials from grains, legumes, nuts, and dried fruits. This device effectively capitalizes on the differences in floating speed and specific weight between the primary product and impurities. As part of its operation, the product is introduced by gravity into a dosing hopper, which ensures a uniform distribution across the width of the destoner. Once the product descends onto a sieve, a combination of vibrations and airflow enables the segregation of heavier contaminants. These impurities are then channeled out, leaving only the cleaned product. Constructed with a frame supported casing made from sheet metal with galvanized profiles, the destoner is available in a variety of sizes and models to accommodate capacities ranging from 800 to 8,000 kg/h.Cleaners and Separators - Industrial Cleaners

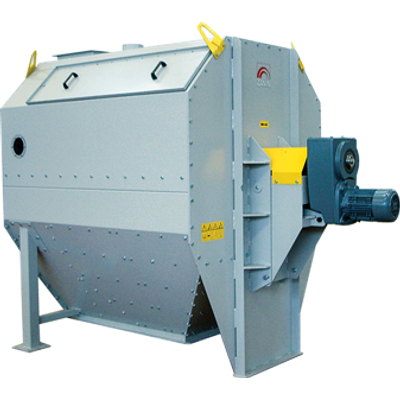

Zanin - Rotary Drum Cleaner for Grain Processing

The TS Rotary Drum Cleaner is engineered to efficiently eliminate large impurities from grain, making it ideal for use in pre-cleaning stages or within receiving systems at facilities like ports or railway stations. It utilizes a gravity-fed cylindrical drum equipped with a fixed screen. As grain passes through, clean particles traverse the perforations while larger contaminants are discharged separately. The screen choice can be customized based on particle size, enhancing the versatility of the cleaner. This system is available in various configurations, handling capacities from 100 to 300 tons per hour, specifically designed for wheat with a density of 0.78 t/m³ and a relative humidity of 14%, accommodating up to a 2% impurity rate. The TS Rotary Drum Cleaner blends precision and efficiency, playing a crucial role in the initial cleaning stages of grain processing.Others

Zanin Fratelli - Dust Stop Dust Collection Hopper

The DS - Dust Stop dust collection hopper is an efficient solution designed to collect dust during product loading operations, thereby eliminating the need for traditional sleeve filtering systems. This system is particularly valuable in industries where dust control is critical, such as in grain processing or chemical manufacturing. It operates by capturing airborne particles as materials are conveyed into storage, ensuring a cleaner and safer work environment. The hopper's construction is robust and capable of being customized with optional feature enhancements to suit specific industrial needs. It integrates seamlessly with existing handling setups, making it a versatile choice. Zanin Fratelli, known for its expertise in industrial equipment, provides detailed specifications and data sheets to support installation and optimization. It represents a strategic investment in improving air quality and operational efficiency in loading processes.Zanin - Drum Malting Machines for Cereals and Sprouted Seeds

For the local production of grain and professional malting. Over the years, the development of malting systems has led to an increasingly restricted selection of malt producers throughout the world, and therefore a much more traceable product. Today, the tendency for local grain production and professional malting, has allowed the production of quality malt for special beers and organic food products.

Turnkey Plant

Zanin - Cleaning and Drying System

Cleaning and drying systems, composed of dryers, conveyors also with silos or warehouses.