- Home

- Companies

- Zanin s.r.l.

- Products

- Zanin - Model PSC5 - Sieve Cleaner

Zanin - Model PSC5 -Sieve Cleaner

Separates fine, medium and large impurities in the product or calibrates using a single or double step system.

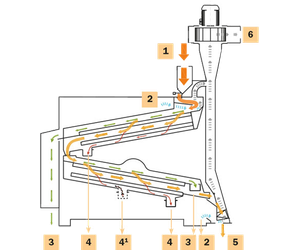

Double step cleaning system. The uncleaned product enters by way of gravity. The counterweight system allows the even distribution of the uncleaned product, which is struck by an air flow that removes the lighter impurities. The product enters the first sieve compartment, containing perforated sheet metal suited to the type of processing. The upper sieve removes the larger impurities, the lower sieve separates the finer impurities. The same processing steps occur in the lower compartment. Before being discharged, the clean product is slowed using decelerators and an air flow removes the lighter impurities, which are sent to a cyclone or filter.

Key

1. Uncleaned product inlet

2. Air inlet

3. Large impurities outlet

4. Fine impurities outlet

4.1 Fine impurities outlet optional

5. Clean product outlet

6. Air with impurities

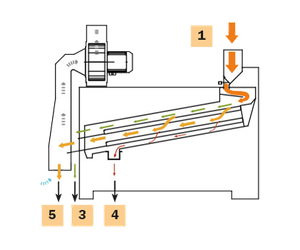

Single step cleaning system. The uncleaned product enters by way of gravity. The counterweight system allows the even distribution of the uncleaned product, which enters the sieve box containing perforated sheet metal, suited to the type of processing. The upper sieve removes the larger impurities, the lower sieve separates the finer impurities.

Key

1. Uncleaned product inlet

3. Large impurities outlet

4. Fine impurities outlet

5. Clean product outlet

- Box supporting frame made of bolted press-formed metal

- Casing in press-formed galvanized metal

- Product feed hopper

- Sieve compartments in carbon steel

- Sieves in perforated carbon steel with sieve holders (frame and sieve holder) and natural rubber beads

- Sieve movement by way of connecting rods

- Painted version.

- Variable fan speed.

- Wear-resistant sheet.

- Electrical control panel.

- Vertical hopper for large impurities.

- Inclined hopper for large impurities.

- Stainless steel sieves.

- Sup-product collection sector.

- Mounting structure.

- Bag placer.

Pre-cleaning capacity 12 t/h (8 t/h for S version), cleaning capacity 8 t/h (4 t/h for S version) and calibration capacity 2 t/h (1 t/h for S version). Capacities calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%.