- Home

- Companies

- Elecster OYJ

- Products

- Elecster - Aseptic Pouch Packaging ...

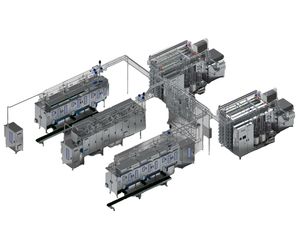

Elecster - Aseptic Pouch Packaging Machines

Reliable and lasting seams: Reliable and lasting seams are guaranteed by permanently heated sealing devices. The temperature of the heat sealing is adjusted with an accurate PID control. The film is sealed inner surface against inner surface. The form of the package is pillow pouch.

Accurate dosing and low packaging material loss: Elecster technology enables to get high quality pouch, vanishing leakage problems and outstanding image printing. Volume based dosing unit is a guarantee for stable and accurate dosing. Automatic film track control and sealing device temperature control ensure minimal packaging material loss.

Complete Elecster assembly consists of

- Maximum capacity 16000 pouches/h

- Pouch sizes 100 – 1300ml

- Adjustable volume

- High level of asepsis

- Easy to operate and maintenance

- Can be equipped with Elecster CIP Unit

High aseptical level

The metering device and the tubing are sterilized by hot water (>121°C). The integrated air sterilizer equipment maintains the aseptic conditions in the sterile chamber and the packaging film tube. The packaging film is sterilized with H2O2 and with powerful UV radiation.

Product shelf-life 180 days

You can optimize your production and gain profitability by using Elecster filling machines with Elecster packaging material, which are developed hand in hand. High aseptical level of packaging machine together with Elecster high quality packaging material enables to reach long product shelf-life from 90 days up to 180 days.

Easy, fast and money saving solution for those who are planning to expand the production capacity. Add another packaging machine to the existing sterilizer or connect another complete UHT line to the existing UHT line.

Flexibility

Elecster Integration System, EIS through its cross-connection panels and ECB signalization box enables to optimize the utilization of sterilizer(s) capacities with several aseptic filling machines/packaging sizes and thus saving investment in expensive aseptic buffer tank.

Sterilizer does not have to be tied to a one specific packaging machine. Sterilizer is able to feed several packaging machines at the same time or separately. By switching the connection between sterilizer and packaging machines you can keep your production running around the clock.