- Home

- Companies

- Northern Dairy Equipment Ltd

- Products

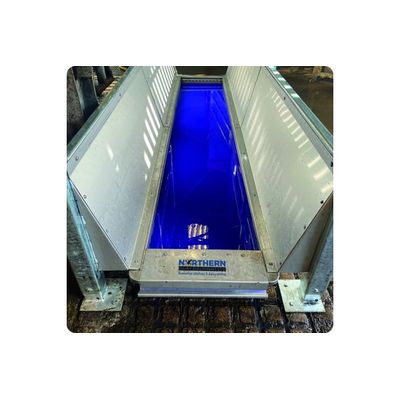

- iBath - Automatic Cattle Footbath

HEALTHIER COWS = HEALTHIER PROFIT

With every case of lameness costing the dairy farmer on average £300 it is very important to ensure that your cows hooves are being treated and disinfected consistently and correctly.

FOOTBATHING DONE RIGHT

The iBath counts the number of cows that walk through the bath and will replenish the water and solution to the farms pre-set adjustment on the iSoftware. The floor of the bath is installed with a thick anti slip hard wearing rubber mat to ensure safe cow flow.

AUTOMATED HYGIENE

Refilling of the bath is carried out through multiple flood valves located in the iBath and can easily be refilled in less than 3 minutes. A unique wash down system ensures all matter is removed from the bath in between each refill cycle.

Another unique feature is the iBaths manual wash cycle that can be done once milking is finished. This feature sprays and floods the bath for additional time to ensure the bath is immaculately clean before the start of the next milking.

BESPOKE TO YOUR FARM

Each iBath is bespoke to each farm and range from specific baths to suit robotic milking systems and baths up to 3.7metres long. Races can also be custom manufactured.

Each farm only needs one iSoftware control unit to power multiple baths – no need for several control units.

SANITISING CHEMICALS

The iBath uses the iBath concentrate product which is a powerful blend of hoof biocides and hoof treatment products. This product is formalin free and can be used at a low rate of 1%, meaning a safer working environment and cost savings

- PHASE 1 : The iBath fills with solution and water within 3 minutes through multiple jets, meaning it’s fastest filling bath in the market.

- PHASE 2 : Cows are counted using a preset programmes in the iSoftware, with settings for both day and night.

- PHASE 3 : When the maximum numbers is reached, the iBath washes-out and refills automatically.

- PHASE 4 : Once a milking cycle has finished, the iBath carries out an extended wash cycle and refills ready for the next milking.