- Home

- Companies

- Teagle Machinery Ltd.

- Products

- Tomahawk - Model 404M-505M-505XLM - ...

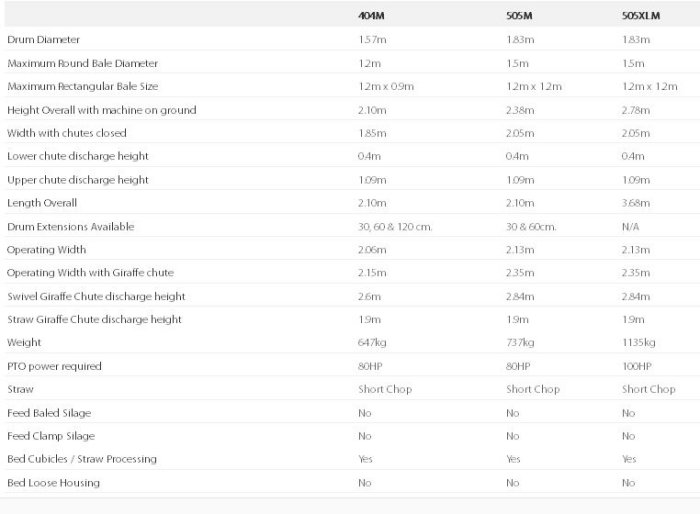

Tomahawk - Model 404M-505M-505XLM -Bale Processor

For straightforward bale processing the 404M/505M/505XLM range offers fast effective milling of straw and miscanthus to a very consistent and fine length.

Operation

Blow straw up to 30`, discharge to one or both sides of the tractor. Alternative delivery chutes are available to suit your requirements.

The Tomahawk 404M, 505M and 505XLM Bale Processors use Blades or Hammers to chop dry material until small enough to pass through the holes in a screen. A range of screens are available with holes from 15mm to 36mm to obtain material of a consistent chop length.

Easy control of output by adjusting the speed of drum rotation.

Configurations

- Tomahawk 404M - Suitable for 1.2m (4`) diameter bales.

- Tomahawk 505M - Suitable for 1.5m (5`) diameter bales.

- Tomahawk 505XLM - Suitable for 1.5m (5`) diameter bales and full size Hesston bales.

Various drum extensions are available for ease of operation or to accommodate larger rectangular bales.

The 404M/505M/505XLM range is suitable for dry material only, and will not cut silage as it will block the mill sieve.

British built and backed

For your peace of mind Tomahawks are backed by an efficient after sales service from our production facility in Cornwall, England.

The Tomahawk Drum models are economical, simple and robust. There are no gearboxes, with the drive to the rotor being direct from the tractor, a hydraulic motor is used to rotate the drum. Due to their simplicity and strength, customers can expect a long service life from their Tomahawk.

Processing

Process your own straw for TMR - no need to stockpile.

Quicker, better TMR mixing with prechopped straw.

Improved palatability - chopped straw improves digestion.

Bedding

Save Straw - users report typical savings of 30% compared to manual bedding down.

Cleaner livestock - healthier animals and fewer disease problems.

Save labour - one person bedding operation.

Specify the right machine for the job - short chop for poultry & cubicles, light shredding for loose housing.

Drum Tomahawks

Simple - drum turns clockwise, rotor turns anti-clockwise, and material is skimmed of the end of the bale.

No gearbox - direct drive from PTO. Hydraulic drive to drum.

Feed rate is controlled by the angle of the drum.

Direct Drive

Direct drive from rotor to shaft - no gearbox.

Choice of Material Chop Length

Length of material is determined by the screen which is fitted. The nature of the material has some effect upon actual shredded length and some variation is likely to occur. Screen sizes available are 10, 12, 15, 18, 21, 28, 36, 50mm holes and 120mm slots.