- Home

- Companies

- Falcon Srl

- Products

- Falcon - Model Ø 45, 60 - Chain ...

Falcon - Model Ø 45, 60 -Chain Livestock Transport Systems

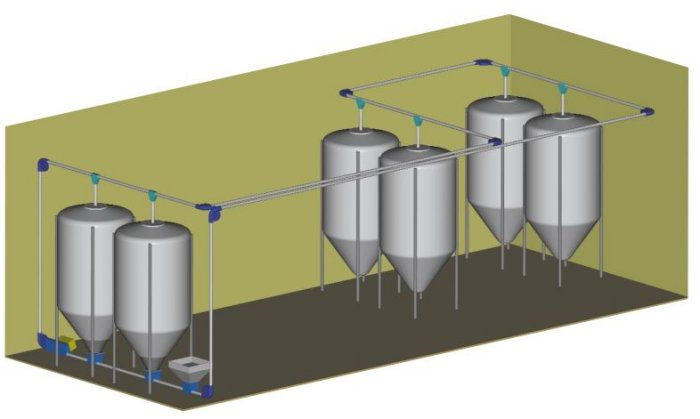

The FALCON System first in the world uses a chain conveyor that has plastic discs moulded to the chain at regular interval. The chain conveyor moves in a continuous circuit the material at high speed. The flexibility of the chain enables it to be installed in almost any configuration.

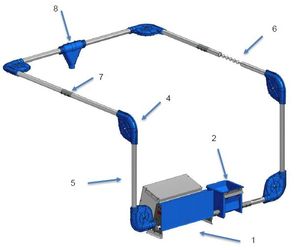

The Falcon Company was the first in the world to use a chain transport system with plastic disks inserted at regular intervals. The chains moves the teed through the circuit at high speed; the flexibility of the chain allows it to be used in any situation. The chain movement is provided by a drive unit. The feed is introduced into the circuit via a hopper; the material can be delivered at any point, via correctly sized holes in the pipe, and using different kinds of flow device (drop tubes, dispensers, etc.)

N°: Description

1: Drive unit

2: Hopper

4: Corner

5: Feeding pipe

6: Chain conveyor

7: Coupler for feeding pipe

8: Discharge valve

The chain movement (6) is driven by a drive unit (1). Feed is introduced into the circuit through a loading hopper (2). The piping (5) can follow various routes thanks to deviation angles (4). Pipe sections are connected using special coupling joints (7). One or more material discharges (8) can be performed at any point along the circuit by using appropriately sized slots on the piping.

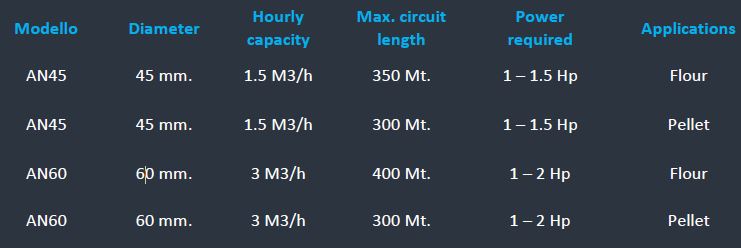

Model Diameter Hourly throughput Maximum circuit length Power required Applications

AN45 45 mm. 1,5 M3/h 350 Mt. 1-1,5 Hp Flour

AN45 45 mm. 1,5 M3/h 300 Mt. 1-1,5 Hp Pellet

AN60 60 mm. 3 M3/h 400 Mt. 1-2 Hp Flour

AN60 60 mm. 3 M3/h 300 Mt. 1-2 Hp Pellet

Special steel chains with plastic discs.

Extremely strong and resistant. Allow:

- Wide field of usage.

- Easy and fast assembly.

- Use of a high number of corner sto vary vertical and horizontal circuit sections.

- Simple maintenance using the open link.

- Hardwearing and compact, they are constructed with a varnished galvanized steel plate casing, or stainless steel

- Direct or belt drive transmission.

- Can be positioned at any point on the circuit.

- Supplied with automatic tension pulley and safety gear switch.

- 1, 2 or 3 ways models, in varnished galvanized steel plate or stainless steel.

- With agitator and flow regulation.

- Can be positioned at any point on the circuit.

- Versions with extraction auger and motorized drive.

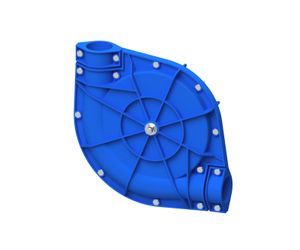

- Available in 90° - 135° - 360° versions for any kind of horizontal or vertical circuit.

- Constructed with a nylon (90°) or aluminium casing (90° -135° - 360°) with cast iron wheels.

Falcon was the first company in the world to utilize a Genoese-style chain transport system equipped with molded plastic discs at regular intervals. The chain transports the feed within the circuit at high speed, and its flexibility allows it to be used in any situation.

Special steel chains with molded plastic discs, highly flexible and durable, offering the following advantages:

- Wide range of applications.

- Easy and quick installations.

Capability for horizontal and vertical directional changes. Easy maintenance, thanks to the open joint design.

Thanks to the flexibility of the chain, spiral, and components, FALCON conveyor systems can easily handle long and winding routes, creating circuits with multiple changes in direction using just a single drive unit. During transport, friction is minimized, resulting in low power consumption. They are designed to ensure a clean working environment, free from dust dispersion, and require minimal maintenance, with quick and infrequent interventions, thereby reducing overall costs.