Zanin s.r.l.

- Home

- Companies

- Zanin s.r.l.

- Products

- Zanin - Model SDZ12, SDZ25 & SDZ50 - ...

Zanin - Model SDZ12, SDZ25 & SDZ50 -Destoner for Cereals

FromZanin s.r.l.

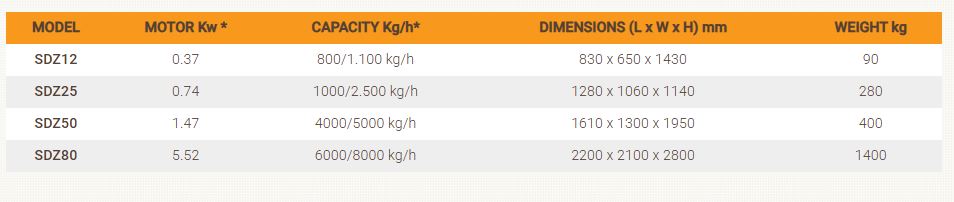

The destoner for cereals is an essential equipment utilized for the separation of heavy impurities such as stones, metals, and other unwanted materials from grains, legumes, nuts, and dried fruits. This device effectively capitalizes on the differences in floating speed and specific weight between the primary product and impurities. As part of its operation, the product is introduced by gravity into a dosing hopper, which ensures a uniform distribution across the width of the destoner. Once the product descends onto a sieve, a combination of vibrations and airflow enables the segregation of heavier contaminants. These impurities are then channeled out, leaving only the cleaned product. Constructed with a frame supported casing made from sheet metal with galvanized profiles, the destoner is available in a variety of sizes and models to accommodate capacities ranging from 800 to 8,000 kg/h.Most popular related searches

destoning

cereal

cereal legumes

grain legumes

seed cleaning

legumes

seeding

grain destoning

seed separator

seed product

Separates heavy impurities (stones, etc.) in grain.

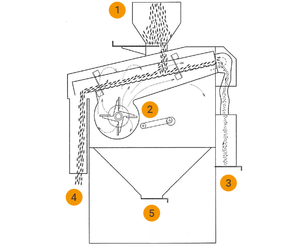

The destoner with an internal fan is used to separate all impurities (such as stones, metals, lumps of earth, glass etc.) from various products like cereals, legums, nuts and dried fruits, which have a different floating speed and specific weight from that of the main product.

The product enters by gravity into a dosing hopper and is evenly distributed over the entire width of the destoner.

The product then descends onto a sieve and the combination of vibration with an airflow separates heavy bodies, which are be channelled into a tarara, from the good product.

Key

1. Product inlet

2. Air inlet

3. Discard outlet

4. Cleaned product outlet

5. Light impurity outlet

Frame supports casing in sheet metal with galvanised sheet profiles

- Folded sheet metal box, painted, with its various elements bolted together

- Product inspection porthole

- Inlet hopper produced with a manual adjustment damper for managing product flow

- Belt-drive motor

- Intake fan

- Available in various sizes and models with capacities from 800 to 8,000 kg/h.