Jinan TCPEL Machinery Co.Ltd

- Home

- Companies

- Jinan TCPEL Machinery Co.Ltd

- Products

- TCPEL - Model TC - Drum Chippers

TCPEL - Model TC - Drum Chippers

TCPEL is a leading drum chippers manufacturer and supplier in China. We have our own factory and our products have been exported to over 100 countries. We design our drum chippers in a manner that it is able to match customer requirement and work as per industry standard. Our team of skilled designers ensures that every product whether compact or commercial is highly effective and gives the desired outcome with minimum power consumption.Most popular related searches

drum chipper

drum wood chipper

wood chipper

mobile drum chipper

chipper wood

forestry wood chipper

forestry wood

chain feeding

mobile chipper

forestry chipper

Are you thinking about buying drum chippers for your home or business? If so, you`ll want to read through this comprehensive guide first. From a forestry wood drum chipper to an industrial drum style wood chipper, there are all kinds of drum chippers out there to help you get rid of unwanted wood. You can even find a mobile drum chipper for sale! Chances are, if you can think of it, you can find it. But how do you choose the best one?

In this guide, we’ll tell you everything you could want to know about drum chippers – we will cover everything from how these tools work to where you can buy one when you’re ready. Let’s dive in!

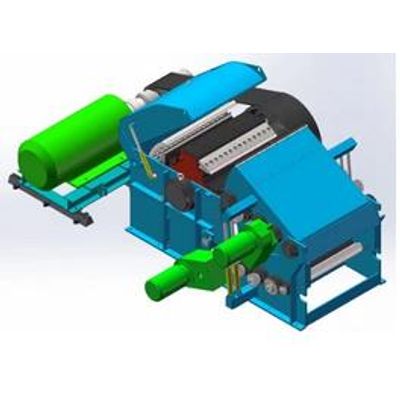

- Our drum wood chipper has several advantages over our competition. We use high-quality and strong materials to produce a long-lasting machine. Features of our drum wood chipper emphasize safety and convenience. We strive to make a machine that is not only the safest to use, but also easy to run and maintain.

- The crushing chamber of the drum wood chipper is covered for safety and the cover lifts easily by hydraulics. This makes maintenance and changing blades easy and convenient.

- The blade material is H13. It is harder and resistant to wearing. It can cut hardwood and has a longer service life before needing sharpening. For best results, the blade should be sharpened after every 1000 hours of use.

- The wood chipper’s feed roller is made of 45# Mn steel. This steel alloy has strong abrasion and a precise bite force, helping to reduce the chance of damage to the chipper.

- The body material is strong carbon steel – Q235. This allows it to run steadily without ground foundation.

- The feeding chain conveyor feeds the raw material evenly, regardless of size or shape, preventing dangerous blockages.

- The screen mesh size can be customized for different sizes to produce end products to specific requirements.