- Home

- Companies

- Gondor Machinery

- Products

- Gondor - Garlic Peeling Production Line ...

Gondor - Garlic Peeling Production Line Machine

Automatic garlic peeling line is featured by food processing industry, restaurant, agricultural product processing enterprise, seasoning and spice producers, and food research and development institutions.

- Brand Name: Gondor

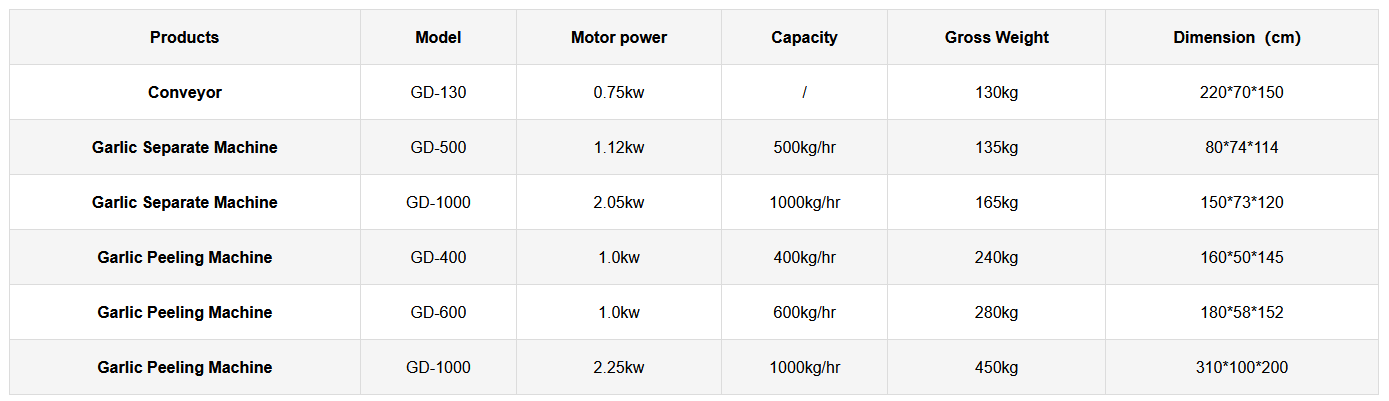

- Power: 0.75KW/1.12KW/2.05KW/1.0KW/1.0KW/2.25KW

- Voltage: 110V, 220V, 380V 50/60Hz

- Machinery Function: Garlic/Onion Peeling

- Core Components: Motor, PLC, Gear, Bearing

- Power Source: Electric

- Weight: 505KG/575KG/745KG

- Material: 304 Stainless Steel

- Capacity: 400kg-1000kg/h

- Peeling Rate: Over 98%

The garlic peeling production line is a set of highly intelligent, efficient, and reliable production systems. It is mainly used for the large-scale separation and peeling of garlic, including an elevator, garlic separator, chain garlic peeling machine and other machines. Gondor machinery provides the garlic peeling processing lines for our customers and our clients span across the globe. And they choose to purchase from Gondor machinery to increase productivity and quality with our advanced machinery or lines. Get in touch with us for a free consultation about the automatic garlic peeling production line in Gondor group!

Different Models of Gondor Garlic Peeling Production Lines

In Gondor machinery, we offer various automatic garlic peeling production line models that can be customized based on the specific requirements of our customers and their desired production capacity. Whether you are looking forward to purchasing a small-scale setup for local production or a larger, industrial-grade line for mass production, the Gondor garlic peeling machine line can be tailored to meet your demands. Moreover, our processing lines for garlic adopt an advanced system that can ensure a seamless transition from whole garlic to perfectly peeled cloves. Furthermore, and even more significantly, it can maintain high productivity and quality throughout the whole process. The bellows are some main models of the garlic peeling production line from Gondor group:

By choosing to buy the automatic garlic peeling production lines in Gondor, businesses can benefit from the combination of high efficiency, superior quality, and reliability. In this way, Gondor machinery can stay competitive in the fast-paced food processing industry. In addition, Gondor automatic garlic peeling production lines are designed for maximum efficiency and speed. We utilize advanced technology to peel large quantities of garlic in a shorter time, reducing labor costs and increasing productivity. The peeling process is streamlined to ensure that each clove is peeled perfectly in a matter of seconds. Check below to know some main features of this production line and contact us for more product details!

-

It is engineered to handle garlic gently, which can preserve the integrity and quality of the cloves. And it is obvious that less waste and higher yield are crucial for businesses looking to maximize their output.Minimal Damage to Garlic

-

Our factory adopts high-quality stainless steel to manufacture our garlic peeling lines, and it is easy to clean and resistant to corrosion. Besides, the unique design also minimizes the risk of contamination, which ensures the highest food safety standards.Hygienic and Safe Operation

-

For the purpose of satisfying the unique needs of different businesses, Gondor offers customized garlic peeling production lines. Therefore, global customers can choose from a range of options and configurations from our factory.Customizable Solutions

-

The automatic system will streamline the entire peeling process. And it can ensures a seamless and consistent operation during the whole process, which can reduce the need for manual intervention.Integrated Automation

-

The machine uses electricity as its energy source, featuring low energy consumption. In addition, the dry stripping method does not pollute the environment and complies with environmental policies.Energy conservation

-

This production lines can be used in various industries such as food processing plants, catering services, and agricultural product processing enterprises.Widely applicable

-

The device has a simple intuitive interface, making it easy to operate. Easy to clean and maintain, meanwhile, reducing downtime.Simple operation

-

The production line is designed with full automation, enabling rapid peeling and significant labor cost savings.High Efficiency

-

Each garlic clove achieves a consistent peeling effect to ensure the stability of product quality.Quality Assurance

-

The equipment has a high performance-to-price ratio. It has a fast return on investment through reduced labor costs and high production efficiency.Cost Effectiveness

-

In addition to garlic, it can also peel onions. Customers can customize production lines to meet specific business needs.Multi-functional