Solar EVA - Model 5 -Greenhouse Film

3 layer coextruded greenhouse film with ant¡-condens additive. The newest technique of coextrusion is used to manufacture Solar EVA film. Solar EVA is coextruded in three layers, giving the film its enormous strength and unbeatable characteristics compared to ordinary greenhouse films.

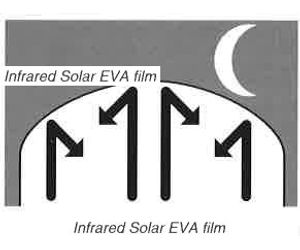

lnfrared rays, causing heat loss during the night are reflected on the EVA copolymers inhibited in the film. As a result the night temperature underneath Solar EVA covered greenhouses will remain at a much higher and stabile level. increased plant activity, higher yields and elimination of night frost risk can be obtained.

To prevent plants and flowers from damaging condens drops formed on the inner film surface during the night, an anticondens additive is inhibited into the inner EVA layer. lnstead of drops an even layer of waterfilm is formed, running down along the film. Less drops means also more light.

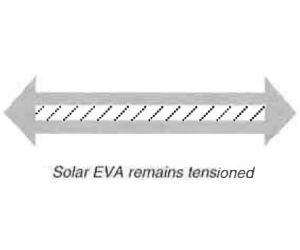

Enormous strength and durability. Since Solar EVA is a coextruded 3 layer film it has superior qualities standard UV films It is very to tension on greenhouses due to its elastic structure. Solar EVA film remains tensioned also during warming up during day time, tight and wrinkle free.

Longer life!

Solar EVA film has an excellent U.V. resistance, beating ordinary U.V. film with an estimate of 2 year extra. This only makes it worth to choose Solar EVA for your greenhouse.

Higher transparency of Solar EVA.

The transmission of light through Solar EVA is exceptionally high compared to ordinary U.V. film. U.V. film 86%, Solar EVA film 90%.

Solar EVA remains clean!

The smooth and anti-static surface of Solar EVA ensures clean film for the period of use.